Nanyang JZJ is a special-purpose material study-oriented enterprise. They utilize a very interesting technique known as energy dispersive x-ray fluorescence. That technique is so important, because it allows scientists to figure out the composition of various materials. The reason knowing about the composition of materials is important is that it enables us to learn how we can utilise these materials in our day to day lives, be it in manufacturing, construction or even art.

What Makes Dispersive X-ray Fluorescence Spectrometry RavishingArtwork{'We Can}(ReducedInterference='DROPPED') X-ray works by using x-rays (type of energy to travel through the things) A strong source generates these x rayed. When x-rays hit a material, they excite the fundamental particles (atoms) in the material to emit light. A detector, a device also used by astronomers, collects this light so researchers can determine what elements the material contains. More like illuminating a puzzle with an external flashlight to see what pieces are in your possession!

This technique is very helpful for a variety of materials. This is effective, for example, for the investigation of metals, ceramics, glass and plastic. Scientists can glean information about how these materials formed, what unusual properties they may include, and how we can perhaps use them for multiple purposes, by looking into the elements that make them up. For example, after figuring out the components in a metal, it will help in deciding whether the metal can be used in stronger setups like buildings or can be used for electronics.

There are several benefits to dispersive x-ray fluorescence spectrometry. This is one of the best aspects it does not harm the material studied so, after the analysis it can still be used for its primary request. This technique is also highly sensitive and can identify trace levels of the various constituents in a material. It becomes essential since we sometimes want to know about minuscule amounts of materials. Yet, there are its shortcomings with this method. It, for instance, has challenges to characterize light elements such as carbon and oxygen, which are abundantly present in various materials. This is also an expensive approach, and may limit some use cases.

Dispersive x-ray fluorescence spectrometry, despite its challenges, still resolves an essential place for scientists. They are always seeking improvements to such a process. Just one example, is to improve the light-element detection capabilities, in order to permit analysis of a broader range of materials. And they still are trying to find a way to make the method cheaper so there are more labs able to run such tests. And scientists are working to speed up the process and make it more accurate, so they can obtain data more quickly and with confidence. That means we will, in the future, be able to use this technology for much more than we do now!

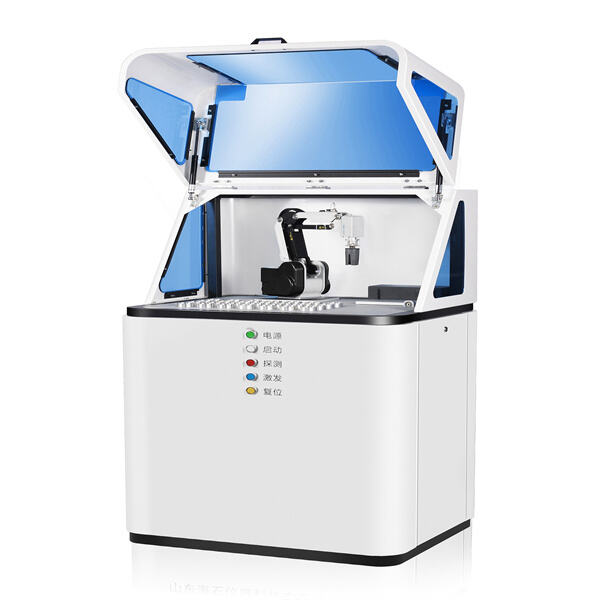

The primary products of the company are high-temperature and medium-temperature heating furnaces as well as sample preparation equipment high-temperature dispersive x-ray fluorescence spectrometry high-temperature furnace linings and computer-controlled systems Chemical reagents for laboratories etc

Our products are used widely in the dispersive x-ray fluorescence spectrometry and ceramics industries, as well as building chemicals, materials, machinery and various other composite materials industries. Through international transport, the main universities affiliated with the company as well as national quality inspection agencies and research laboratories and refractory material and other production units, as well as steel units are shipped to areas and countries within Asia, Europe and Middle East. Transportation methods: We offer air transportation, sea transportation, express delivery and rail transportation.

Our high-quality products are mainly due to the fact that we do not just have skilled engineers for application, but also design engineers who pay close attention to dispersive x-ray fluorescence spectrometry and the operation. With rich high-temperature testing experience We can offer custom test instruments for individual projects. We also provide customers with high-temperature testing technologies Consulting and testing of samples; as well as comprehensive and complete laboratory solutions.

With a continuous RD investments, technological advancement and improvement in product quality, the company has successively been awarded ISO9001, CE, dispersive x-ray fluorescence spectrometry and other certifications. It also has CMC national production license for measuring instruments in the refractory business, as well as independent intellectual property rights as well as more than 50 national invention patents and utility model patents.