- Descripción general

- Consulta

- Productos relacionados

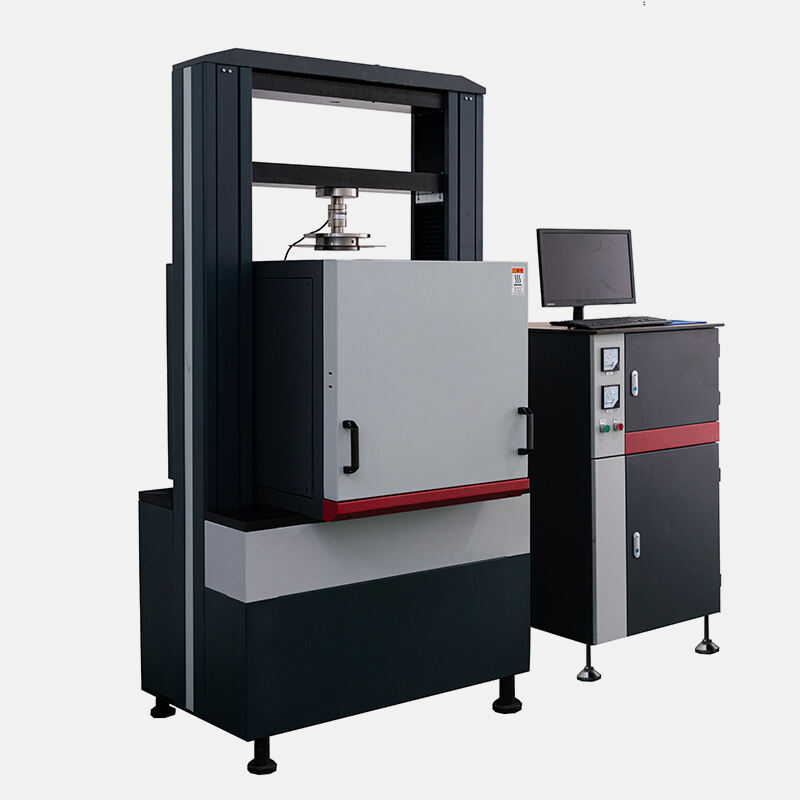

Diseñado principalmente para la sinterización de cerámicas técnicas (como prótesis dentales de zirconio).

Equipado con una plataforma elevadora eléctrica, el horno calefactor cilíndrico garantiza una distribución uniforme de la temperatura.

Los materiales se colocan en recipientes de carga hechos de cerámica industrial.

Hasta tres recipientes de carga pueden apilarse, lo que asegura una alta eficiencia de producción.

Parámetros Estándar

Temperatura máxima de operación: 1700 °C

Volumen de la cámara del horno: 1, 2, 4, 16 L

Estructura de carcasa doble con dispositivo de enfriamiento por ventilador, baja temperatura en la pared exterior

Calefacción con elementos calefactores especiales de MoSi₂, resistente a reacciones químicas

Cámara del horno y material aislante térmico de material cerámico espumado nuevo de ahorro energético con junta machihembrada, no contaminante y sin escoria

Método de suspensión especial en la parte superior del horno para garantizar alta resistencia a temperaturas elevadas

La mesa de trabajo utiliza un dispositivo eléctrico de accionamiento por tornillo de bolas de alta precisión

Parte superior del horno equipada con puerto de escape

Sistema de control táctil TCP de alto nivel

Función de limitación de corriente del transformador dedicado

Función de protección de arranque suave a baja temperatura del elemento calefactor

Accesorios opcionales:

Contenedores de carga apilables, es posible hasta tres capas

Sistema de distribución de gas manual o automático

Interfaz de gas protector o gas reactivo

Entrada de gas ajustable en la parte inferior del horno

Límite de protección contra sobrecalentamiento

| Especificaciones y modelos |

Temperatura de funcionamiento °C |

Dimensiones del horno (mm) |

Volumen L |

Precisión del control de la temperatura ℃ |

Fuerza KW |

Voltaje v |

tiempo de calentamiento (min) |

Peso del equipo (kg) |

HTF.DSF01/17 |

1650 |

φ120*100 |

1 |

±1 |

2.2 |

220 |

90 |

50 |

HTF.DSF02/17 |

1650 |

φ180*185 |

2 |

±1 |

3.2 |

220 |

90 |

50 |

HTF.DSF04/17 |

1650 |

φ200*200 |

4 |

±1 |

5.5 |

220 |

90 |

80 |

HTF.DSF16/17 |

1650 |

φ260*260 |

16 |

±1 |

12 |

380 |

90 |

200 |

EN

EN

AR

AR

BG

BG

FR

FR

DE

DE

HI

HI

IT

IT

PL

PL

PT

PT

RU

RU

ES

ES

TL

TL

IW

IW

ID

ID

UK

UK

VI

VI

TH

TH

TR

TR

FA

FA

MS

MS

UR

UR

BN

BN

KM

KM

LO

LO

PA

PA

MY

MY

KK

KK