Machines à perles de verre XRF Vous vous demandez ce qu'est le verre XRF ? Ces machines sont fascinantes ! Lisez la suite pour découvrir comment elles nous aident dans l'analyse des perles de verre, en fournissant des résultats rapides et précis, et en améliorant la manière dont nous traitons nos produits en verre. Nous verrons également ce qu'est la technologie XRF et son fonctionnement, ainsi que pourquoi tant les fabricants que les étudiants en droit devraient comprendre son importance.

Découvrir ce qui se trouve dans les perles en verre était autrefois difficile et fastidieux. Cela nécessitait des méthodes complexes qui n'étaient pas très efficaces. Cependant, aujourd'hui, la technologie XRF vient à notre rescousse ! XRF = Fluorescence de Rayonnement X. Cela signifie l'utilisation de rayons X par ces machines uniques afin de déterminer quels éléments sont présents dans un morceau de verre. Elles peuvent facilement déterminer la composition d'une perle en verre en examinant les matériaux utilisés pour la produire. C'est comme si nous possédions un superpouvoir qui nous permet de voir à travers le verre.

Les machines à boules de verre XRF sont rapides et fiables. Grâce à quelques boules de verre, elles peuvent nous dire en quelques minutes ce qu'il y a dans ces boules de verre ! Cela est important pour les fabricants car ils ont besoin de savoir si les produits qu'ils mettent sur le marché sont bons ou non. En cas de problèmes, ils peuvent les résoudre rapidement. Avec ces résultats rapides, des économies considérables de temps et d'argent peuvent être réalisées, car les fabricants n'ont pas à attendre de longues analyses de laboratoire qui pourraient prendre plusieurs jours ou semaines. Ils peuvent ainsi obtenir immédiatement les informations nécessaires pour prendre de meilleures décisions.

Alors, comment la machine à perles de verre XRF vous aide-t-elle à fabriquer du verre avec elle ? Elle nous fournit des informations exactes sur ce qui se trouve dans le verre. Cela aide les fabricants à ne pas commettre d'erreurs pendant la production. Leur connaissance des matériaux spécifiques que chaque méthode utilise leur permet de s'assurer que le verre est de qualité supérieure. De plus, ces machines peuvent être utilisées pendant la production du verre, permettant ainsi aux fabricants d'évaluer la qualité dès le début. Cela permet un contrôle plus strict de la qualité du produit final, des livraisons client plus fiables et moins de problèmes en aval.

L'analyse chimique peut être un sujet difficile à aborder, surtout pour les enfants qui sont relativement nouveaux en science. Souvent, vous avez tout type de mathématiques désagréables, y compris des formules complexes et des équations difficiles. Mais, avec les machines à perles en verre XRF, c'est facile et amusant ! Les mathématiques complexes sont évitées, et les étudiants peuvent apprécier comment les rayons X ordinaires révèlent la constitution élémentaire d'un échantillon. Rien ne vaut une expérience pratique, et c'est l'une des raisons pour lesquelles les jeunes apprenants s'interconnectent facilement avec la science. Laissez-les voir la technologie en action et comment elle nous permet de calculer des choses qui seraient normalement faites avec un crayon, mais cette méthode est moins efficace pour l'analyse.

L'un des plus grands avantages à utiliser des machines à perles de verre avec XRF est qu'elles fournissent des détails spécifiques sur les perles de verre. Grâce à cette analyse minutieuse, les fabricants peuvent identifier comment ils pourraient devoir modifier leurs produits pour les améliorer et les rendre plus sûrs. Lorsqu'ils fabriquent du verre, ils peuvent également vérifier qu'ils utilisent des matériaux de qualité. C'est important car si nous les utilisons en toute sécurité, les produits finaux sont également sûrs à l'utilisation par n'importe qui. Et tout cela repose sur votre contrôle qualité et sur la précision avec laquelle vous connaissez chaque pièce de verre.

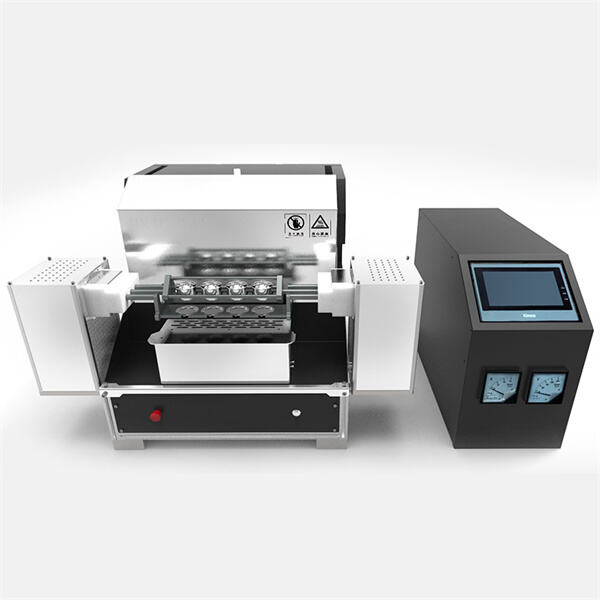

Les principaux produits de l'entreprise incluent des machines de fusion automatiques pour l'analyse spectrale ainsi que des tests physiques sur les performances des fibres céramiques non formées et formées qui sont des Machines à Boules de Verre XRF Électriques et d'autres produits tels que fours chauffants moyenne et haute température, équipements de préparation d'échantillons, éléments chauffants haute température, doublures de fours haute température, systèmes de contrôle par ordinateur et instruments, réactifs chimiques de laboratoire, etc.

Les machines à billes de verre XRF et les produits électriques sont largement utilisés dans les industries de la métallurgie et de la céramique, ainsi que dans les matériaux de construction, la chimie, la machinerie et d'autres industries de matériaux composites. Par le biais du transport international, les grandes universités de l'entreprise, ainsi que les agences nationales de contrôle qualité, les laboratoires de recherche, les unités de production de matériaux réfractaires et les unités sidérurgiques sont expédiées vers des régions et des pays d'Asie, d'Europe et du Moyen-Orient. Méthodes de transport : Nous prenons en charge le transport maritime, le transport aérien, la livraison express et le transport ferroviaire.

Nous sommes fiers de nos produits de première qualité XRF Glass Bead Machines Electric, car nous ne sommes pas seulement des ingénieurs d'application expérimentés, mais aussi des ingénieurs de conception qui prêtent attention aux détails et à l'exploitation. Nous avons une grande expérience des tests à haute température et nous sommes en mesure d'offrir des équipements de test conçus sur mesure pour des tâches particulières. Nous fournissons également des services de conseil en technologie à haute température ainsi que des tests d'échantillons.

Grâce à des investissements continus en R&D, des progrès technologiques et une amélioration de la qualité des produits, l'entreprise a successivement obtenu les certifications ISO9001, CE, SGS et diverses autres certifications. Elle possède également la licence nationale CMC pour la fabrication d'instruments de mesure pour les XRF Glass Bead Machines Electric, soutenue par des droits de propriété intellectuelle indépendants, ainsi que plus de 50 brevets d'invention sur le marché national et des brevets de modèle utilitaire.