- סקירה

- פרמטר

- חֲקִירָה

- מוצרים קשורים

היכנסו

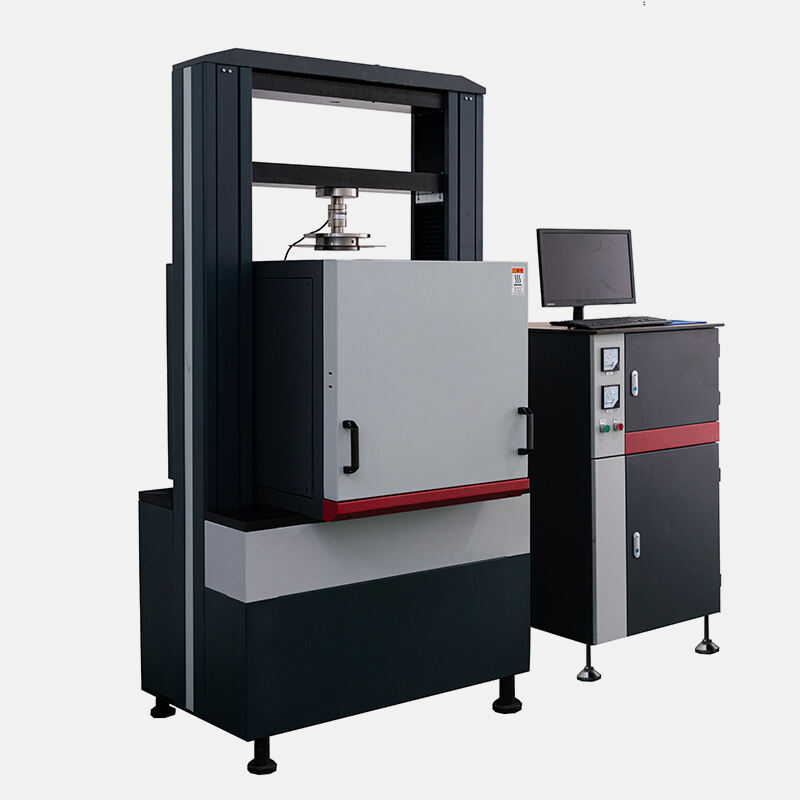

כור חימצון חשמלי

● כרסית תנור עצמאית, נפח מיכל גדול, מתאים לניסויים ולייצור בתחומים רבים;

● דיוק גבוה בקרת טמפרטורה, אחידות גבוהה ויציבות של טמפרטורת התנור;

● בקרה פנאומטית של דלת פתיחה משופעת, שמאפשרת תפעול קל, תוך שמירה על דלת התנור החמה רחוקה מהמפעיל;

● פלט התראה אוטומטית על חום מופרז ואמצעי הגנה אחרים למניעת תאונות;

● המנפחת בעלת חיים ארוכים בשימוש, והחיצונית עשויה אבנים כרמיות בידוד גבוהות עם יעילות בידוד טובה.

בקרת טמפרטורה

● בקרה אלקטרונית ואוטומטית, מקסימום 1200°C

● תרמוקרוז מסוג K.

● פלט התראת חום גבוה.

יתרון ניתוח אש

1. ניסוח מייצג טוב: 줄ל את שגיאת הדגימה למינימום;

2. התאמה רחבה: ניתן להתאים כמעט לכל סוגי הדגימות, מחרסיות, ריכוז זהב ועד לזהב לצרכיה ולאנטימוניט שלא ניתנות לפתרון בשיטת הרטובה;

3. יעילות עשירון גבוהה: יותר מעשרת אלפים פעמים, כמות קטנה של זהב וכסף יכולה לעשור כמותית לכפתור הזהב הנבדק מדוגמיות של עשרות גרמים המכילות כמות גדולה של יסודות מטריצה;

4. תוצאות ניתוח מהימנות ודקות גבוהה: ניתוח באש מתאים לדוגמיות עם תוכן זהב של <1μg~1g, והדיוק טוב יותר מהשיטות האנליזה הכליות האחרות.

הרכבה

המדגם המפורר משוקל ומעורבב עם חומר נמס. מוסיפים עופרת כאלקטור. את המדגם מחממים תנור בטמפרטורה של כ-1000 מעלות. לאחר כ-20 דקות, המדגם מתמוסס והמתכות היקרות והעופרת מופרדות מסlags הסיליקט ונוצרת מה שנקרא 'כפתור' בתחתית הגבעול. כפתור זה מכיל את המתכות היקרות.

כיבוש

ברגע שהמדגם מוסר מהתנור ומתקרר, כפתור העופרת מופרד מסlags הסיליקט. המתכות היקרות מופקות בתהליך הידוע בכיבוש. במהלך הכיבוש, העופרת בכפתור מאבדת אלקטרונים ומספוגת לתוך הכוסל, ומשאירת גרגיר של מתכת יקרה הידוע כפריל. את תוכן הזהב בפריל קובעים או על ידי שקלול (גרביטציונית) או באמצעות התמוססות באקו רגיה.

אנליזה וגילוי

לאחר שהזהב, הפлатינום והפלדיום במحلول, ניתן לנתח אותם באמצעות ספיגת אטומים בלהט (AA)

מקרה פרוייקט

EN

EN

AR

AR

BG

BG

FR

FR

DE

DE

HI

HI

IT

IT

PL

PL

PT

PT

RU

RU

ES

ES

TL

TL

IW

IW

ID

ID

UK

UK

VI

VI

TH

TH

TR

TR

FA

FA

MS

MS

UR

UR

BN

BN

KM

KM

LO

LO

PA

PA

MY

MY

KK

KK