Hello everyone! Sorry, but you can not call it X-ray Fluorescence Spectroscopy but we will learn how XRF can work today. Because X-ray Fluorescence Spectroscopy is a non-destructive analytical technique. It also means, we can view the items in the sample without having to destroy the sample or harm the contents. There it detects X-rays emitted by a sample that has been targeted by a different X-ray source.

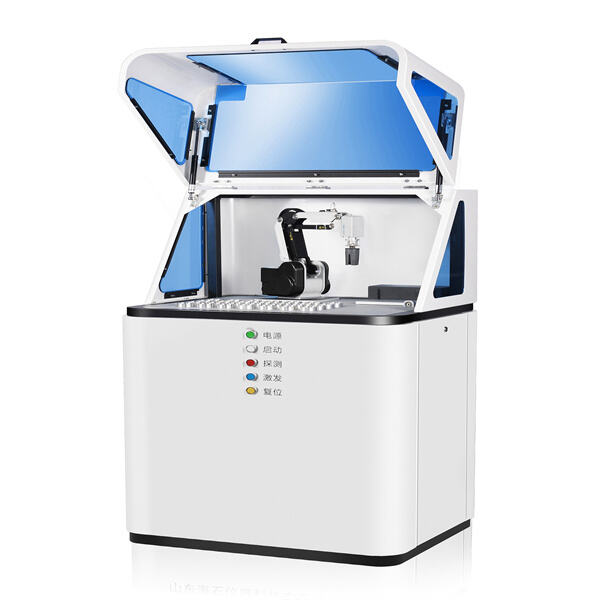

There are many salient components within the XRF tool, which work together in order for the tool to operate properly. The first is a holder for the sample where we introduce the material under evaluation. Then comes the source of X-rays (X-ray source) which generates the X-rays utilized for interaction with the sample. Then we have the detectors. These detectors are unique in the sense that they measure reflected X-rays from the sample that has been interacted with. Lastly, there are electronics that allow the tool to function properly and to process the information received from the detectors.

Nanyang JZJMaking great upgrades on the tools used inXRF. The micro-focus X-ray source is among the top new features. This new kind of source lets the tool view ultra-tiny samples more clearly than ever before. In other words we can do great results with tiny pieces of material. Multi-element detectors are another great development. The detectors, which can detect and quantify X-rays of multiple elements simultaneously. This is really useful as it helps make the XRF tests quicker and more precise. All of these advances allow for faster and lower-error results for scientists and researchers.

Another integral part of any XRF tool are the detectors. They have to detect the X-rays that are emitted from the sample after it has been stimulated by the X-ray source. There are numerous detectors of various types. The most common, for example, are the solid-state and gas-filled detectors. Note: Solid-state detectors have been used more frequently in recent years than photographic plates as they are more sensitive to X-rays. This allows them to detect even the trivial levels of X-rays. They also respond quickly, so the results can be delivered faster.

Checking and calibrating XRF instruments is key to ensuring that XRF tools provide the correct results each and every time. The process of checking this is referred to as calibration. Calibration of the tool is done by modifying the tool so that it generates the right signals as per standards which are known. It's akin to calibrating a scale so it takes ceaseless measurements of weight accurately. Standardisation is another vital process. Standardisation: Here, we check whether the tool is working in fine order using specialty reference materials. Nanyan JZJ has established innovative methods for achieving calibration and establishing standards that assist to guarantee that the utmost accurate XRF readings are obtained. This means we can have confidence in the results generated by the XRF tests.

X-ray tubes are the most standard method of generating X-rays used in XRF tools. These tubes create X-rays, utilizing an intense electric current. Once the current is high enough, this creates X-rays, which are subsequently aimed at the sample you are testing. The X-rays from these sources excite the sample, which creates its own fluorescent X-ray that is measured by the detectors. Different methods exist to produce X-rays (like radioisotope sources or laser ablation). But since each approach has its own pros and cons, the specific testing requirement will help you determine if you should go with one or the other.

The company's continual RD investment, instrumentation of x-ray fluorescence spectroscopy advances and improvements in product quality have resulted in successive ISO9001, CE and SGS certifications. It also has CMC national production licenses for measuring instruments for the refractory industry, with its own intellectual property rights and more than 50 national invention patents as well as utility model patents.

The primary products offered by the company include automated sample melting machines that are used for spectral analysis as well as physical performance testing instruments for instrumentation of x-ray fluorescence spectroscopy unshaped ceramic fibers refractory products other products medium and high temperature heating furnaces equipment for preparation of samples high temperature heating elements high temperature furnace linings computers controlling systems instruments Laboratory chemical reagents and other

We are very proud of our high-quality products because we are not just experienced application engineers but also design engineers that are attentive to the smallest details and operate. With a instrumentation of x-ray fluorescence spectroscopy of high-temperature test experience we can supply custom test instruments for individual projects. We can also provide users with high-temperature testing technology Consulting and sample testing services; providing comprehensive and complete laboratory solutions.

Our products are widely used in the metallurgy and ceramics industries and also in building chemicals, materials, machinery and other composite material industry. Through international transportation, major institutions of the company along with national quality control agencies and scientific research centers and refractory material and other production units, as well as steel units are shipped to regions and countries in Asia, instrumentation of x-ray fluorescence spectroscopy and Middle East. Methods for transportation: We provide air transport, sea transportation, express delivery and railway transportation.