- Overview

- Parameter

- Inquiry

- Related Products

Product Introducation

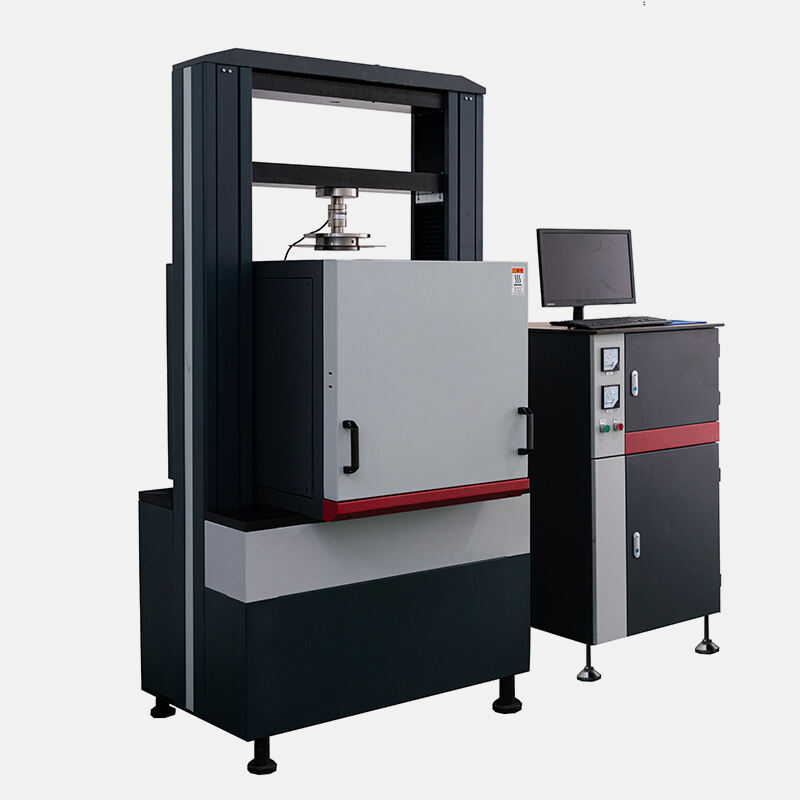

The HNJC-L4E XRF fused bead sample preparation machine upgrade on HNJC-L4D version after long time market testing, specially designed for the harsh working environment, and integrates the operational advantages of high efficiency, multi-function, convenient use, high security, etc. The HNJC series XRF fusion machine are professional corollary equipments of fusion sample testing for “X-ray fluorescence analyzer”. It prepares sample to glass sample by adopting glass fusion method, which greatly reduces the basic effect and mineral effect of ore, rock, soil, refractory material, raw material of metallurgy, etc in “X-ray fluorescence spectroscopic analysis”, and greatly improves the accuracy and precision of analysis. It can be widely used in many industries, such as iron and steel, metallurgy, chemical industry, geology, cement, ceramics, refractory material.

Technical Features

1. High reliability

The HNJC-L4E melting prototype has been thoroughly upgraded based on old version. After a long time of tests in a harsh and demanding working environment, it can operate stably for a long time in a 24-hour continuous working and become a reliable partner for X-ray fluorescence area.

2. High work efficiency

The fusion machine adopts a six head combined design, which is suitable for the preparation of medium batch samples and large batch samples. It is a real full-automatic sample melting equipment without reverse molding.

3. Good temperature control effect

The furnace chamber is made of special furnace chamber materials, and adopts multi-layer special refractory materials for heat preservation and insulation technology. The heating speed is fast, the furnace temperature is uniform and stable, and the heat preservation accuracy can reach ±1°C. The fusion machine adopts a six-head combined design, which is suitable for large-scale samples preparation. Sample injection molding and pot bottom molding can be selected at will, one-time molding or inverted molding can be selected arbitrarily, and 4 samples can be melted in 15-26 minutes.

4. Good fusion sample effect

The machine adopts the advanced design of the furnace body swinging back and forth and the sample rack spinning simultaneously to ensure the eddy current movement of the sample melt, which can achieve good uniformity and air bubble removal effect.

5. Suitable for melting samples at different temperatures for various materials

This machine adopts silicon carbon rod heating, S-type platinum rhodium thermocouple temperature measurement, LCD touch screen + PLC + AI artificial intelligence control, a new intelligent man-machine operating system, has the characteristics of fault self-checking, easy operation, reliable operation, etc., parameters The default design makes the operation simpler, safer, more automated, and more precise in temperature control. It can achieve high-quality fusion samples at different temperatures for various materials. It has excellent analysis reproducibility and can meet various industries of analytical standard requirements.

Specifications

| Automatic control system | Touch screen + AI intelligent control temperature controller + PLC |

| Working tempeture | 0~1250℃ |

| Temperature raising speed | Average 45℃/min (support customized 100℃/min) |

| Heating element | Silicon carbide rod |

| Temperature control | S-type thermocouple |

| Temperature control accuracy | ±1℃ |

| Sample quantity | 4 |

| Fusion sample speed | 10-26 mins/4pcs |

| Furnace swing type | Two-way swing |

| Furnace swing angle | Swing forward 0~15°;swing backward 0~40° |

| Head bracket rotation speed | 17r/min |

| Control system | Provide 9 working curves |

| Heating output control | SCR phase-shift trigger control |

| Rated current | 30A |

| Rated frequency | 50Hz |

| Max power | 8kW (Commonly used power 2-5 kW) |

| Weight | 380KG |

| Dimension | 1120mm×560mm×1000mm |

| Power requirement | Heating furnace power: 380V、40A 50Hz |

| Control and mechanical power: 220V、10A 50Hz |

EN

EN

AR

AR

BG

BG

FR

FR

DE

DE

HI

HI

IT

IT

PL

PL

PT

PT

RU

RU

ES

ES

TL

TL

IW

IW

ID

ID

UK

UK

VI

VI

TH

TH

TR

TR

FA

FA

MS

MS

UR

UR

BN

BN

KM

KM

LO

LO

PA

PA

MY

MY

KK

KK