X-ray fluorescence (XRF) analysis is a unique technique for material explorations. This technique employs X-ray radiation to identify the variety of elements present in different types of samples. The Xrays we use in this process look like those doctors use in hospitals to look inside our body, but these are more powerful and more energetic. In this article, we will explore the principles of operation of XRF, the locations of its utilization, as well as how to conduct sample preparation in the right way for XRF so that we get the optimal result.

One of the most important things about XRF analysis is that it is a non-destructive technique, and as such the materials undergoing testing will not be harmed in any way. It can be used to identify the composition of metals, minerals, plastics and other materials. When a material is bombarded by high-energy X-rays it emits its own X-ray radiation. This radiation is then measured by scientists and used to determine the types and quantities of elements contained within the material. This approach is extremely useful for scientists and researchers. DFW has two basic variants namely, Energy Dispersive X-ray Fluorescence (EDXRF) and Wavelength Dispersive X-ray Fluorescence (WDXRF). Each has its own unique applications and benefits.

This makes XRF essential in several industries, from mining, medicine, environmental testing, and even product manufacturing. One such application of XRF is as a non-destructive method in the mining industry that provides essential information to scientists on ore samples. This helps in determining whether the ore can be profitably mined. XRF works on the principle of safety of materials coming into factories to be used for testing in the medicine field. It can also help to make sure that chemical waste gets disposed of correctly. With its high-speed analysis and sensitivity to low concentrations, XRF can also be used for environmental testing to identify pollution in contaminated soil, air filters, and sources of pollution water. XRF ensures that metals or minerals are the right amounts, are utilized in the manufacture of items that make up electronics to manufacture products.

Aside from ordinary solid samples, XRF also has the capacity to examine liquids and micro or small samples. Now that renders it an extremely multi-purpose tool. This is one of the fastest and cheapest ways to investigate materials such as metals, ceramics and minerals. Several factors influence the results of XRF, so proper precaution is required to achieve an accurate XRF analysis. This depends on various factors such as the quality of the sample preparation, the concentration of the elements present in the sample, and the sensitivity of the XRF instrument. XRF has many merits, including the fact that even traces of elements in a sample can be detected, which is valuable information to scientists who need it.

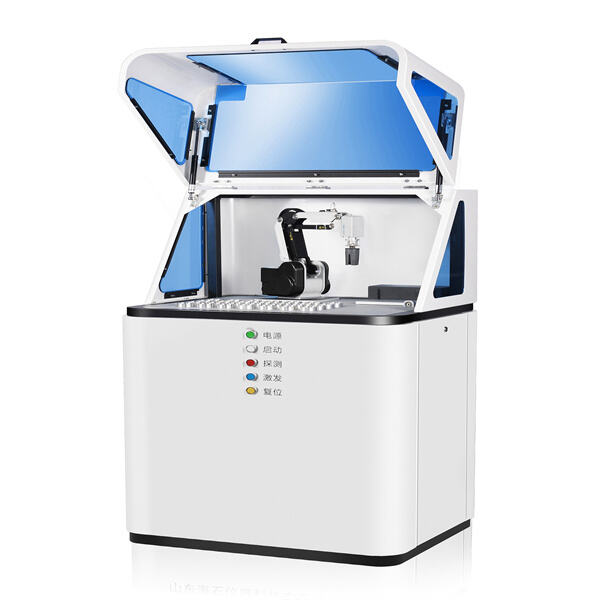

There are ongoing improvements to the XRF tool providing quicker testing and higher accuracy. This can be very powerful especially in cases demanding very small XRF analyses with the new tools called microfocus XRF available on the market. Many of these more sophisticated instruments can also be configured to generate maps pinpointing where particular species are found on a surface, providing a wealth of valuable information for researchers. Moreover, an innovative technology on detectors has enabled portable XRF tools that are used by scientists in the field, performing tests on-the-spot instead of in a laboratory environment. Modern X-ray fluorescence devices also feature intelligent software that compensates for various factors that can affect results. This state-of-the-art software can further provide refinement to the analysis, increasing accuracy.

Preparing samples for XRF analysis is the single most critical variable necessary for obtaining acceptable results. This preparation consists of diminishing the sample and mixing it up properly so it produces reliable analysis. Cleaning varies depending on the application but is always essential to eliminate dirt, dust, and oil that can affect the outcome. For liquid samples, you might need to dilute it or treat your sample differently to prepare it for testing. Common methods of preparation for solid samples are grinding to powder, fusion and pellet pressing. In addition, the sample holder should also fit the corresponding testing protocol. This is significant as holders may be having rough surfaces thereby altering the measurements, which may then affect the result.

x-ray fluorescence of materials superior products are due to the fact that we not only have experienced engineers in the field in addition to design engineers who pay close attention to detail and operational. We have years of expertise in high-temperature tests and we can provide custom test equipment for particular projects. We also offer high-temperature technology consultancy services as well as sample testing.

The company's ongoing RD investments, technological advancement and improvements in product quality have led to successive ISO9001, x-ray fluorescence of materials and SGS certifications. It also has CMC national production license for measuring instruments in the refractory business, as well as independent intellectual property rights and more than 50 national invention patents and utility model patents.

The main products of the company are heating furnaces for high and medium temperatures and sample x-ray fluorescence of materials high-temperature heating equipment furnace linings as well as computer controlled systems laboratory chemical reagents as well as other chemical reagents

Our products are widely used in the metallurgy and ceramics industries and also in building chemicals, materials, machinery and other composite material industry. Through international transportation, major institutions of the company along with national quality control agencies and scientific research centers and refractory material and other production units, as well as steel units are shipped to regions and countries in Asia, x-ray fluorescence of materials and Middle East. Methods for transportation: We provide air transport, sea transportation, express delivery and railway transportation.