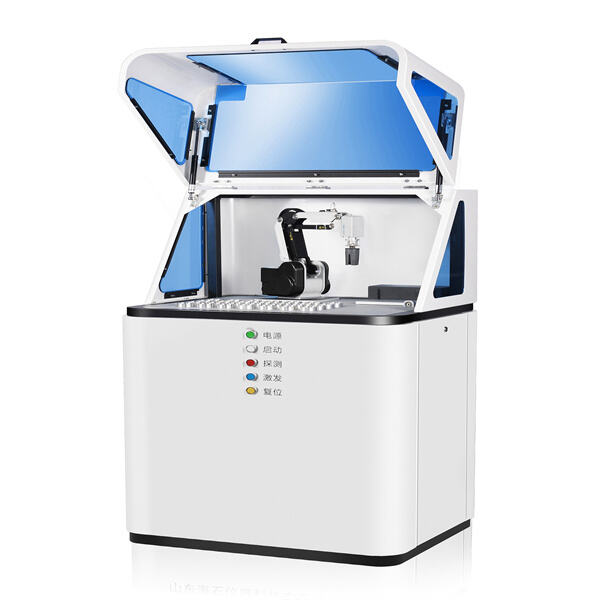

آلة دمج XRF التي تحتاج إلى معرفتها. هي الأداة الفضولية جدًا الموجودة، آلة إعداد العينات لكرات الانصهار XRF . هذه الآلة تساعدنا في اكتشاف المزيد عن المواد المختلفة الموجودة في بيئتنا. تعتمد على تقنية تُعرف باسم التلألؤ السيني.

اقتباس اليوم: يمكن اختبار几乎所有 الأشياء بسرعة ولدرجة عالية جدًا من الدقة! - تعمل آلة دمج XRF على إرسال أشعة سينية إلى المادة التي نريد التحقق منها. نانيانغ JZJ انصهار XRF ثم تراقب كيف يتم انعكاس الأشعة السينية مرة أخرى من سطحها. هذا الانعكاس يحتوي على وجود أنواع مختلفة من العناصر الجزيئية الموجودة في ذلك المادة والتي يمكن للمachine تحليلها. بفضل هذه العمليات السهلة والسريعة، يمكننا التعلم بسرعة كبيرة مما يتكون الشيء.

جهاز دمج XRF - مهم لاختبار المواد في المستقبل. عند مقارنته بالماضي، فإنه يساعد العلماء والعاملين كثيرًا في تحديد تركيبة الأشياء. اختبار المواد قبل هذا الجهاز الرائع يستغرق وقتًا طويلاً كما أنه معقد للغاية. كان يتطلب إجراء العديد من اختبارات المعادن في المختبر، مما قد يستغرق أيامًا أو حتى أسابيع. ولكن مع جهاز نانيانج JZJ جهاز الدمج التلقائي لـ XRF ,يمكننا اكتشاف ذلك اليوم في أحد أكبر تجار التجزئة الخاص بهم، لذا فهو أسرع بكثير.

على الرغم من استخدامه ل-Calibration آلة الانصهار XRF، يعمل هذا الجهاز بشكل مثالي أيضًا. على سبيل المثال، في محل المجوهرات قد تجد نفسك تريد معرفة ما إذا كان شيء يُباع كونه ذهبًا صلبًا هو بالفعل ذهب خالص. هذا جهاز إعداد العينات لتحليل XRF ضروري لأنه يتيح لك تسعير المجوهرات بشكل صحيح وكذلك ضمان رضا عملائك. لا شيء يستحق البيع إذا تبيّن أنه ليس قيمًا كما تعتقد، مما يؤدي إلى عملاء سيئين، بين أمور أخرى. بالإضافة إلى ذلك، يستخدم البعض هذه الأجهزة لضمان اتخاذ القرارات الصحيحة عند اختيار المواد لمشاريعهم.

بينما نحن نتحدث عن هذا الموضوع، فإن جهاز دمج XRF هو أداة رائعة لاختبار تنوع المواد. الآن أصبحت الدuality مهمة جدًا للعلم والصناعة لأنها تُوحّد بسهولة من مصادر متعددة إلى أرقام في البيانات. إنه مصدر قيم جدًا للكثير من المهنيين حيث يمكنهم تحليل ومقارنة المواد بسرعة باستخدام هذه الأداة.

منتجاتنا ذات الجودة العالية لأننا لا نمتلك فقط مهندسين مهرة في المجال، بالإضافة إلى مهندسي تصميم يركزون على التفاصيل والتشغيل لجهاز XRF Fusion Machine. لدينا سنوات من الخبرة في اختبارات درجات الحرارة العالية ونستطيع تقديم معدات اختبار مصممة خصيصًا للمهام الخاصة. كما نوفر أيضًا خدمات استشارية للتكنولوجيا العالية الحرارة واختبار العينات.

المنتجات الرئيسية للشركة هي أفران التدفئة لدرجات الحرارة المتوسطة والعالية ومعدات تدفئة عينات XRF Fusion Machine بدرجات حرارة عالية وأجزاء الأفران، وكذلك أنظمة التحكم بالكمبيوتر، والمواد الكيميائية المعملية وغيرها من المواد الكيميائية

استثمار الشركة المستمر في الأبحاث والتطوير (RD)، والتقدم التكنولوجي وتحسين جودة منتجاتها أدى إلى الحصول على شهادات متتالية مثل ISO9001، CE وSGS. كما تمتلك الشركة رخصة إنتاج أجهزة القياس الوطنية لجهاز XRF Fusion Machine، والتي تشمل حقوق فكرية حصرية في قطاع المواد الحرارية بالإضافة إلى أكثر من 50 براءة اختراع وبراءات استخدام.

تُستخدم منتجاتنا بشكل واسع في صناعات السيراميك والميتالورجيا، وكذلك في الكيماويات الإنشائية، والمواد، وأجهزة XRF Fusion Machine وصناعات المواد المركبة الأخرى. تتعاون الجامعات الرئيسية للشركة مع وكالات الفحص الوطني وجودة المنتجات، ومراكز البحث العلمي، وشركات إنتاج المواد الحرارية ووحدات الصلب. يتم تصدير المنتجات عبر النقل الدولي إلى المناطق والدول في آسيا وأوروبا والشرق الأوسط وإفريقيا. طرق النقل: يمكننا دعم الشحن الجوي، والنقل البحري، والشحن السريع، والنقل بالسكك الحديدية.