Comprendre l'Analyse XRF

Une vidéo différente sur cette technique spéciale qui aide les scientifiques à déterminer quels éléments se trouvent dans divers matériaux (analyse XRF). Cela est pratique car avec cette méthode, les scientifiques peuvent tester beaucoup de choses comme des roches, du sol ou peut-être des bijoux, tout comme le produit Nanyang JZJ appelé machine de préparation d'échantillons pour XRF n'est-ce pas fascinant ? L'appareil utilisé dans le processus est appelé analyseur XRF. Mais cet instrument donne des résultats vierges, ce qui signifie qu'il n'y a rien à craindre pour l'instant dans les échantillons ; car avant qu'une machine comme celle-ci puisse fonctionner et fournir de bons résultats, les scientifiques doivent d'abord fabriquer ce qu'on appelle des perles fondues.

Qu'est-ce que les perles fondues - Elles ressemblent à de petites billes en verre. Pour préparer ces perles, une très petite quantité d'échantillon que vous souhaitez analyser est mélangée avec un autre matériau appelé fluage et les deux sont fondus ensemble. Le fait de faire fondre est crucial car il décompose le matériau en ses formes élémentaires, ce qui permet de les voir et de les distinguer facilement avec un analyseur XRF. Il y a eu des cas où les tests ont produit des résultats inexactes - Ce qui peut être un casse-tête pour les enquêteurs essayant de comprendre ce qu'ils voient, si nos perles synthétiques n'ont pas été correctement préparées.

Les scientifiques ont besoin du plus de détails possible sur les matériaux testés. Je veux dire, si un scientifique sait quels sont les atomes dans leur matériau, ils peuvent les compter et découvrir une quantité incroyable d'informations à son sujet (l'échantillon), de manière similaire à la Perles fondues pour XRF fabriqué par Nanyang JZJ. Cette connaissance est significative pour nous car elle peut nous aider à éviter la pollution, ce qui contribuera à sauver notre Terre et notre environnement. Par exemple, grâce à cette méthode, les scientifiques peuvent obtenir des informations sur les différentes couches et types de roche présents dans la Terre. De tels données peuvent être très utiles pour l'étude des formations géologiques. De plus, en ce qui concerne les bijoux, le type d'ingrédients contenus peut également déterminer si vous regardez un minéral de base ou quelque chose de bien plus coûteux et de valeur.

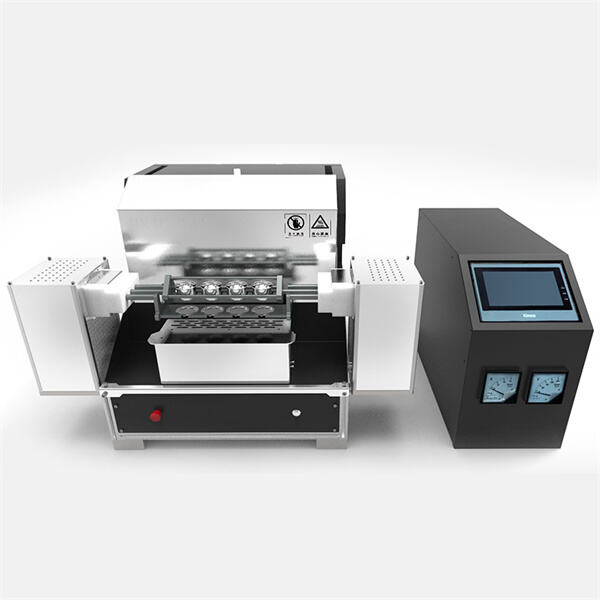

L'une des problèmes que rencontraient les scientifiques était que fabriquer de très bons perles fondues à la main est un processus manuel qui nécessite un travail de qualité, et prend de nombreuses heures même pour un opérateur expérimenté, de plus, le produit Nanyang JZJ tel que Système de fusion en perles XRF automatisé introduisons une machine spéciale appelée machine de fusion qui aide dans ce processus. Les perles sont fabriquées naturellement par la machine de fusion, ce qui économise du temps et réduit la charge de travail. La machine de fusion est bien plus abordable et efficace que la fabrication manuelle de ces perles. Cette technologie économise du temps, permettant aux scientifiques de consacrer davantage d'heures de recherche précieuses aux véritables questions scientifiques plutôt qu'à la préparation des perles.

Elle peut être un atout majeur pour révolutionner la manière dont les tests XRF sont réalisés dans leur ensemble, ainsi que Méthode de plaque Conductomètre thermique développée par Nanyang JZJ. Les perles fabriquées par la machine sont également de taille et de forme uniformes, contrairement à celles faites à la main. Les scientifiques ont besoin de cette uniformité pour effectuer des mesures précises. Avoir des perles uniformes permet d'obtenir des résultats plus précis en utilisant un analyseur XRF. Cela donne aux chercheurs une plus grande confiance dans leurs tests, ce qui peut fournir des connaissances et analyses meilleures sur les matériaux qu'ils étudient.

Les perles fondues sont uniformes en taille et en forme, ce qui est crucial pour l'analyse XRF afin de minimiser les différences entre les échantillons ou les formes, de même que pour celles de Nanyang JZJ. Machines à perles de verre XRF électriques . Cette cohérence leur permet d'être mieux emballées et alignées dans l'analyseur XRF. Comme les perles sont uniformes, chaque lecture prise par l'analyseur est plus précise et reproductible. Cela aboutit à une analyse élémentaire plus exacte, ce qui signifie qu'il sera possible d'identifier précisément les éléments présents dans les échantillons de matériaux analysés. Des perles fondues constantes conduisent à des données et résultats plus fiables que les scientifiques utiliseront dans leurs recherches.

Nous sommes très fiers de notre équipement de haute qualité, car nous disposons non seulement d'ingénieurs d'application expérimentés, mais aussi d'ingénieurs conception qui prêtent attention aux plus petits détails et la machine à fusion continue prépare des perles fondues pour l'analyse XRF. Avec une riche expérience en essais à haute température, nous pouvons fournir des instruments thermiques personnalisés pour des projets individuels ; offrir aux utilisateurs des services de consultation et d'essai à haute température ainsi que des solutions de laboratoire complètes et intégrées.

Grâce à des investissements continus en R&D, des progrès technologiques et une amélioration de la qualité des produits, l'entreprise a successivement obtenu les certifications ISO9001, CE, SGS et diverses autres. Elle possède également la licence nationale CMC pour la fabrication d'instruments de mesure, relative à la machine Fusion qui prépare des perles fondues pour l'analyse XRF, soutenue par des droits de propriété intellectuelle indépendants, ainsi que plus de 50 brevets d'invention sur le marché national ainsi que des brevets de modèle d'utilité.

La machine de fusion prépare des perles fondues pour l'analyse XRF. Les produits sont largement utilisés dans les industries de la métallurgie et de la céramique, ainsi que dans les matériaux de construction, la chimie, la machinerie et d'autres industries de matériaux composites. Par le biais du transport international, les grandes universités de l'entreprise, ainsi que les agences nationales de contrôle qualité et les laboratoires de recherche, ainsi que les unités de production de matériaux réfractaires et les unités sidérurgiques, sont expédiées vers des régions et des pays en Asie, en Europe et au Moyen-Orient. Méthodes de transport : Nous soutenons le transport maritime, le transport aérien, la livraison express et le transport ferroviaire.

La machine Fusion prépare des perles fondues pour l'analyse XRF de l'entreprise, qui sont des équipements automatiques de fusion d'échantillons pour l'analyse spectrale ainsi que des instruments de test de performance physique pour les produits céramiques fibres réfractaires sans forme et non moulées et d'autres produits. Fours chauffants à moyenne et haute température, équipements de préparation d'échantillons, éléments chauffants à haute température, doublures de fours à haute température, systèmes de contrôle informatique, instruments, réactifs chimiques de laboratoire et autres.