- Vue d'ensemble

- Paramètre

- Demande

- Produits associés

Description du produit

JZJ Test est l'un des fabricants et fournisseurs les plus fiables de concasseur à mâchoires avec diviseur d'échantillons rotatif combiné - type résidu en Chine, reconnu pour la qualité de ses produits et ses prix compétitifs. Veuillez être assurés d'acheter auprès de notre usine un concasseur à mâchoires personnalisé avec diviseur d'échantillons rotatif combiné - type résidu.

Introduction

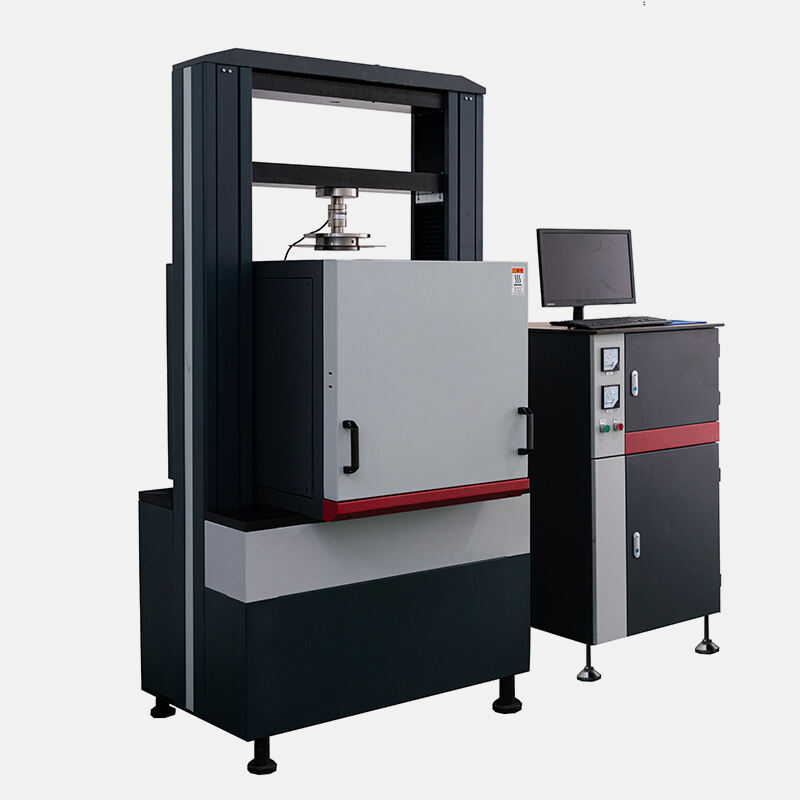

Concasseur à mâchoires avec séparateur d'échantillons rotatif combiné - Type résiduel

Un ensemble qui combine broyage et division en une seule opération. La manipulation est réduite et davantage d'échantillons peuvent être produits. Plus besoin de craindre les erreurs humaines ou l'application incorrecte des procédures.

Les plaques de mâchoire sont en acier au chrome offrant une bonne résistance à l'usure, adaptées au broyage et au fractionnement de charbon, de coke ou de matériaux solides en vrac de dureté moyenne afin de préparer des échantillons.

Le diviseur d'échantillons est conçu de manière ergonomique avec des godets en acier inoxydable résistant à la corrosion et une goulotte d'élimination des refus. Les godets d'échantillonnage sont disponibles dans une gamme pratique de tailles. Des découpages standards des godets à 5 %, 10 %, 12,5 %, 15 %, 20 % et 25 % sont proposés. Le reste du produit alimenté passe vers un conteneur résiduel amovible ou peut être évacué comme déchet.

CARACTÉRISTIQUES

*Efficacité élevée, broyage et division automatiques, aucune intervention manuelle nécessaire ;

*La plaque de mâchoire est en acier au chrome avec une bonne résistance à l'usure, ce qui convient pour le broyage et le rétrécissement de matériaux tels que l'alliage de silicium-manganèse, l'alliage de ferrochrome, l'alliage de ferromolybdène et les minerais d'alliages de terres rares ;

*Mécatronique, dispositif de réglage de la granulométrie avec échelle numérique ;

*Dispositif de lubrification automatique ;

*La vitesse de division est réglable, les godets sont en acier inoxydable 304 ;

*Conception entièrement scellée, aucune pollution par poussière ;

*Le système d'évacuation des résidus permet aux matériaux résiduels de s'écouler directement dans un système de décharge, réduisant ainsi au minimum la manipulation.

Paramètre technique

| Modèle | JZJ-HJD125X150R |

| Matériau de la plaque de mâchoire | Acier à chrome |

| Taille d'entrée (mm) | ≤100mm |

| Taille de sortie (mm) | 3-20 réglable |

| Taille minimale de sortie (mm) | ≤3 |

| Débit (kg/h) | 500-3000 |

| Vitesse de l'arbre vertical (tr/min) | 285 |

| Volume total des godets diviseurs | 20L |

| Seau standard | 8 |

| Puissance du concasseur à mâchoires (kW) | 4 |

| Puissance du système RSD (kW) | 0.55 |

| Alimentation | 380V/50Hz |

| Taille totale (mm) | L1890 x P935 x H1750 |

| Poids (kg) | 702 |

| Respectueux de l'Environnement | Livré avec couvercle anti-poussière et raccord de canalisation |

| Système d'évacuation des résidus | Ce design permet aux matériaux résiduels de s'écouler directement vers un système d'évacuation, réduisant ainsi la manipulation au minimum. |

EN

EN

AR

AR

BG

BG

FR

FR

DE

DE

HI

HI

IT

IT

PL

PL

PT

PT

RU

RU

ES

ES

TL

TL

IW

IW

ID

ID

UK

UK

VI

VI

TH

TH

TR

TR

FA

FA

MS

MS

UR

UR

BN

BN

KM

KM

LO

LO

PA

PA

MY

MY

KK

KK