Как се използва рентгено-флуоресцентната машина за съединяване в индустрията на огнеупорни материали?

Прилагането на машини за флуоресцентен рентген в индустрията на огнеупори предимно се изразява в технологията им за подготовка на високотемпературно топене, която произвежда еднородни стъклени листове без минерали и частици за анализ чрез рентгенов флуоресцентен анализ (XRF), посредством което се подобрява точността и ефективността на химичния анализ на състава. Следните са конкретни прилагани сценарии и технически характеристики:

I. Основни сценарии за прилагане

Точен анализ на химичния състав

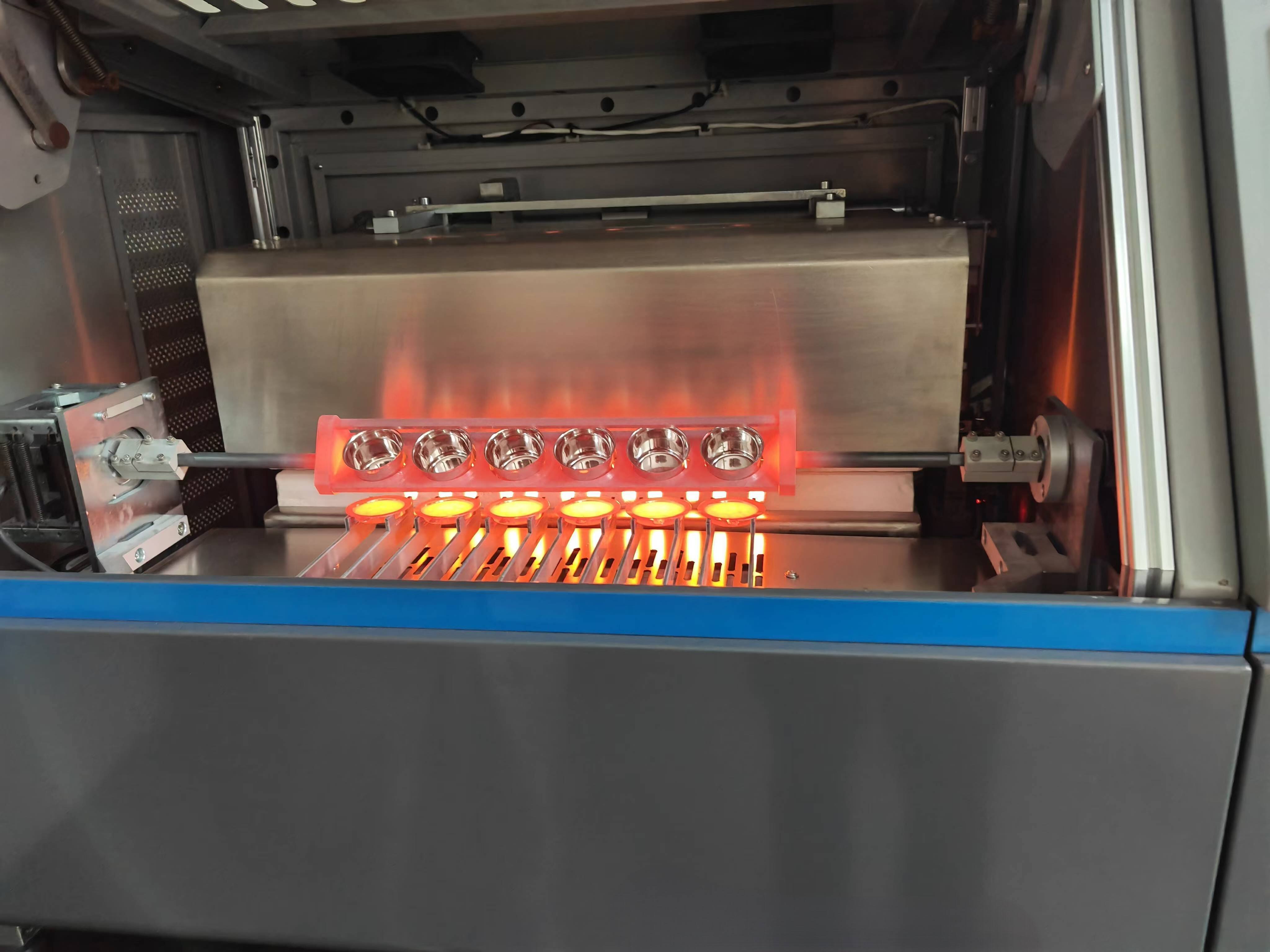

Огнеупорните материали изискват тестване за съдържание на компоненти с висока температура на топене като алуминиев оксид (Al₂O₃), магнезиев оксид (MgO), силициев оксид (SiO₂) и калциев оксид (CaO). Машини за флуоресцентен рентген с фузия разтопяват пробата и флюса в еднородна стъклена лента при високи температури (обикновено 1100-1250°C), като по този начин се елиминират ефектите от частици и минерали, свързани с традиционните методи на пресоване на прах, и се подобрява значително точността на рентгеновата флуоресцентна анализа. Например, машината за фузия Haina HNJC-L6D позволява едновременно разтопяване на шест проби, което я прави подходяща за мащабно тестване на огнеупорни материали.

Предварителна обработка на сложни проби

Огнеупорните материали често съдържат огнеупорни компоненти като карбиди и нитриди. Високата температура и осцилиращият дизайн на машината за сплавяване (като ±55° двупосочно осцилиране + въртене) способстват за отлично смесване на пробите и премахване на въздушни мехури, осигурявайки еднородни разтопени смеси. Например, предварителната оксидационна функция на машината за сплавяване ESI-900 опростява процеса на обработка на проби като феросплавове, намалявайки ръчния труд.

Стандартизиран процес на тестване

Според национални стандарти (като GB/T 21114-2007), машината за сплавяване в комбинация с рентгенов спектрометър може бързо да анализира състава на огнеупорни материали, включвайки анализ от основни елементи (като Al и Si) до следи от елементи (като F и N), което отговаря на изискванията за контрол на качеството в индустрията.

II. Технически предимства и съвместимост с индустрията

1. Високотемпературни характеристики и точност на контрола на температурата

Топенето на огнеупорни материали изисква високотемпературна среда. Модели като Haina HNJC-L6D могат да достигнат температура до 1250°C, с точност на контрола на температурата в рамките на ±1°C, което осигурява пълното топене на компоненти с висока температура на топене без загуби от сублимация. Някои модели използват нов материал за пещи от циркониев корунд с устойчивост на температура до 1350°C, което удължава експлоатационния им живот.

2. Автоматизация и подобрена ефективност

Пълноавтоматични машини за стопяване на проби (като HNJC-T4) поддържат програмиране чрез сензорен екран и операция с едно докосване. С роботизирана ръка за автоматично зареждане и изтегляне на проби могат да обработват 4 до 6 проби едновременно, със скорост на топене от приблизително 10 до 18 минути на партида, което значително подобрява ефективността на лабораторията.

3. Устойчивост на корозия и безопасен дизайн

Топенето с огнеупорен материал може да освободи корозивни газове (като халогени). Вградени вентилационни канали за дим и киселиноустойчиви керамични скоби (като HNJC-L6D) минимизират корозията върху пещта и тигела. Няколко защитни функции (сигнализация за прекомерна температура и защита от изгаряне) осигуряват безопасна работа.

III. Типично сравнение на оборудване и препоръки за избор

Модел Максимална температура Позиция за топене Основна функция Приложна ситуация

JZJ HNJC-L6D 1250°C 6-позиционно Двойно люлеене + въртене, Вентилационен канал Високо-напрежение и висока прецизност при инспекция

Препоръки за избор:

• За тестване в големи обеми: Предпочитайте модели с 6 станции (като HNJC-L6D или ESI-900), които поддържат обработка на няколко станции в паралел.

• За високоточно тестване: Фокусирайте се върху точността на контрола на температурата (±0,1°C до ±1°C) и ъгъла на люлеене (40° до 55°), за да се осигури еднородност на топенето.

• За специални проби: Изберете модели с предварително оксидиране или корозионно-устойчиви конструкции, подходящи за сложни проби като феросплави и огнеупорни материали, съдържащи въглерод.

IV. Тенденции и предизвикателства в развитието на индустрията

1. Интелигентност и интеграция

Бъдещите машини за сплавяне ще бъдат още по-дълбоко интегрирани с системи за контрол на температурата с изкуствен интелект и възможности за дистанционен мониторинг, което ще позволи автоматизирано записване и анализ на данни и ще стимулира интелигентното развитие на изпитването на огнеупорни материали. 2. Екологичност и устойчивост

Огнеупорната индустрия подчертава ефективното използване на ресурси. Машините за сплавяне трябва допълнително да намалят консумацията на енергия (например чрез използване на индукционно загряване с висока честота) и да се адаптират към изискванията за тестване на рециклирани суровини.

3. Повишаване на високотемпературните характеристики

Докато огнеупорните материали се развиват към ултрависоки температури (>2000°C), машините за топене трябва да подобрят температурната устойчивост на нагревателните елементи (например пръти от силициев карбид) и материалите на пещите, за да отговарят на изискванията за тестване на новите материали.

Обобщение: Машините за топене чрез флуоресцентен рентген, с тяхната ефективна и прецизна технология за подготовка на проби, са станали основно оборудване за анализ на химичния състав в огнеупорната индустрия. Високата им температурна устойчивост, автоматизираният дизайн и корозионната устойчивост значително подобряват ефективността на тестването и надеждността на данните. Докато огнеупорните материали се развиват към по-висока производителност и екологични характеристики, машините за топене ще трябва да се оптимизират допълнително, за да отговарят на по-високите технически стандарти.

Препоръчани продукти

Горчиви новини

-

Ръководство за покупка на високопроизводителна и икономична машина за изпитване на огъваща якост при високи температури

2026-02-12

-

Ръководство за работа с машината за изпитване на огъване при висока температура: Дори начинаещите могат лесно да започнат.

2026-02-03

-

В сътрудничество с китайски производители индустрията на никел и желязна руда в Индонезия направи значителна крачка напред в процеса си на модернизация – автоматизираната апаратура JZJ допринася за подобряване на ефективността и точността при тестването.

2026-01-19

-

Задължително за прочитане за начинаещи! Ръководство за избягване на капани при закупуване на машина за огъване при висока температура.

2026-01-12

-

От Нанян до Източна Африка: Китайската технология „огнев анализ“ осветява бъдещето на минната индустрия на Кения — Пускане в експлоатация на контейнерната лаборатория за изпитвателно оборудване Киргизко-Китайско

2025-12-30

-

Характеристики на пещта за изгаряне на златен пепел

2025-12-22

-

Точното измерване на „издръжливостта“ на материали при високи температури — уредът за изпитване на пълзене под товар при висока температура на Nanyang JZJ Testing Equipment Co., Ltd. се експортира в Съединените американски щати.

2025-12-17

-

Надеждният избор на африканските минни гиганти! Nanyang JZJ Testing внася прецизно „ядрено питание“ в златодобивната индустрия на Зимбабве.

2025-12-08

-

Принцип на работа и област на приложение на уреда за изпитване на абразивно износване при околна температура

2025-11-07

-

Основните реактиви, използвани при огнев анализ и тяхната функция

2025-10-13

EN

EN

AR

AR

BG

BG

FR

FR

DE

DE

HI

HI

IT

IT

PL

PL

PT

PT

RU

RU

ES

ES

TL

TL

IW

IW

ID

ID

UK

UK

VI

VI

TH

TH

TR

TR

FA

FA

MS

MS

UR

UR

BN

BN

KM

KM

LO

LO

PA

PA

MY

MY

KK

KK