Y a-t-il quelqu'un qui s'est déjà demandé, quelle est la composition de certains objets ? Avez-vous, par exemple, réfléchi à la manière dont les scientifiques connaissent les propriétés de divers matériaux ? Un outil absolument unique au Centre de Recherche en Chimie de la Découverte qui nous permet d'apprendre la composition de différents matériaux est la spectrométrie de fluorescence X, ou XRF pour faire court. C'est un outil formidable qui vous dit quels composants sont présents dans un objet sans avoir besoin de le démonter. Un peu comme agiter une baguette magique pour que les matériaux nous révèlent leurs secrets. L'utilisation de la XRF pour enseigner au monde ce qui se trouve dans vos matériaux est ce qu'une entreprise nommée Nanyang JZJ fait en utilisant la XRF.

Si nous voulons découvrir ce dont cette chose est faite, nous pourrions supposer que nous devons la casser pour voir son intérieur. Mais ce n'est pas toujours vrai ! L'analyse XRF nous informe sur les matériaux avec un minimum ou sans aucun dommage. C'est une fonction extrêmement utile, car beaucoup de nos objets quotidiens sont soit précieux, soit fragiles. Étapes de la méthode de fluorescence des rayons X (XRF) : Commencez par envoyer des rayons X vers l'objet. Lorsque ce faisceau de rayons X rencontre l'objet, il excite les composants minuscules présents dans les atomes du matériau, qui émettent leurs propres signatures aux rayons X. Nous pouvons identifier de quoi le matériau est constitué en fonction des niveaux d'énergie de ces rayons X. Un peu comme l'analyse élémentaire non destructive - Nanyang JZJ, c'est l'une des méthodes les plus largement utilisées pour acquérir des connaissances scientifiques, suffisantes pour tout le monde.

La spectrométrie de fluorescence X est une technique qui, bien qu'elle ne vous dise pas ce qu'est un objet (la composition), peut être votre baguette magique en cas de besoin. Cela ouvre un monde d'utilisations pour cette incroyable technologie ! Par exemple, la XRF peut aider à vérifier la qualité des matériaux dans les produits. Cela permet aux entreprises de s'assurer que ce qu'elles vendent est sûr et fiable. Elle peut même être utilisée pour examiner des matériaux afin de vérifier s'ils respectent certaines règles et critères. Ce sont des normes essentielles pour la sécurité des humains. Même en archéologie, la science des objets et sites anciens, la XRF trouve son application. Les archéologues peuvent étudier des objets anciens comme des pots ou des outils sans les détruire. L'un des meilleurs aspects de la XRF est qu'elle le fait sans endommager les artefacts et matériaux que nous étudions, nous permettant ainsi d'en apprendre plus sans altération. Un deuxième avantage est que la XRF peut analyser la plupart des éléments simultanément, nous donnant des informations détaillées sur ce qui compose un matériau. Cela garantit qu'il s'agit d'un outil extrêmement utile pour les scientifiques et chercheurs.

Vous vous demandez peut-être comment la fluorescence des rayons X (XRF) pourrait fonctionner, mais en réalité, c'est tout simplement de la science ! Comment fonctionne la XRF ? La XRF fonctionne en excitant de petites particules dans les atomes appelées électrons. Les électrons excités font émettre des rayons X par les atomes ; nous mesurons cela pour obtenir des informations sur les éléments. Un petit morceau d'échantillon ou de matériau est placé et scanné dans un type de machine pour XRF. La machine émet ensuite des rayons X qui excitent les atomes du matériau. Lorsque les rayons X frappent le matériau, les atomes émettent leurs propres rayons X. Elle mesure ensuite ces rayons X et analyse les données pour déterminer quels éléments sont présents dans le matériau.

De nombreuses industries, de la fabrication à la production alimentaire, accordent une grande importance au contrôle qualité et aux tests de matériaux en laboratoire. Nanyang JZJ améliore leur norme de garantie avec l'XRF ; puisque le matériau utilisé doit être sûr, fiable et de confiance, tout en protégeant et en résolvant d'éventuelles pertes futures. L'XRF est un outil polyvalent qui peut caractériser une variété de types de matériaux : métaux, plastiques, électronique, et même les aliments. Ces matériaux artificiels contiennent certains composés chimiques qui peuvent être nocifs et indésirables, donc les éléments doivent être vérifiés afin de déterminer les éléments nocifs qu'ils contiennent et s'ils sont utiles ou non pour le public, afin de ne pas nuire aux gens. C'est également une grande partie des tests de matériaux car il vérifie que les matériaux fonctionneront comme prévu et pourront répondre à certaines spécifications. L'XRF permet aux entreprises de s'assurer que leurs matériaux sont prêts à être utilisés et adaptés à l'usage.

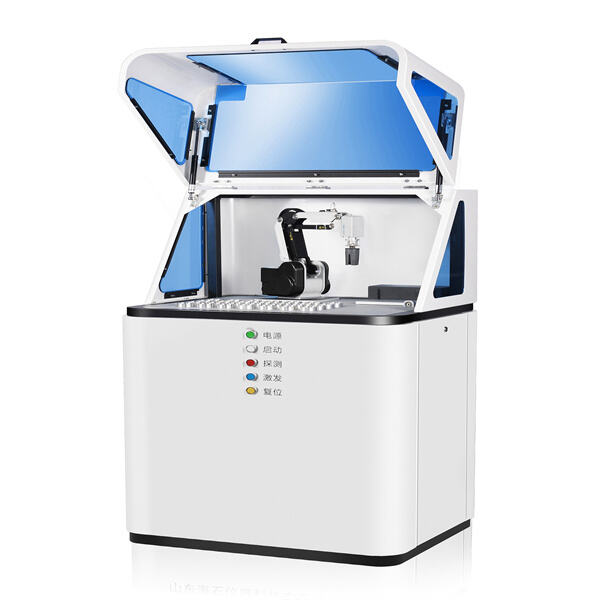

Nous sommes très fiers de nos produits de spectrométrie de fluorescence X car nous ne sommes pas seulement des ingénieurs d'application expérimentés, mais aussi des ingénieurs de conception qui se concentrent sur les détails et l'opérationnel. Nous disposons d'une vaste expertise en tests à haute température et sommes en mesure de fournir des équipements de test thermique personnalisés pour des projets spécifiques. Nous offrons également des services de consultation en technologie haute température ainsi que des tests d'échantillons.

Grâce à des investissements continus en R&D, des progrès technologiques et une amélioration de la qualité des produits, l'entreprise a successivement obtenu les certifications ISO9001, CE, SGS et diverses autres certifications. Elle possède également la licence nationale CMC pour la production d'instruments de mesure pour la spectrométrie de fluorescence X, soutenue par des droits de propriété intellectuelle indépendants, ainsi que plus de 50 brevets d'invention sur le marché national, ainsi que des brevets modèles d'utilité.

Les principaux produits de l'entreprise sont des fours de chauffage pour hautes et moyennes températures, ainsi que des équipements de chauffage à haute température pour la spectrométrie de fluorescence X, des doublures de four et des systèmes de contrôle informatisé. L'entreprise propose également des réactifs chimiques de laboratoire et d'autres réactifs chimiques.

les produits de spectrométrie de fluorescence X sont largement utilisés dans les industries de la métallurgie et de la céramique, ainsi que dans les matériaux de construction, la chimie, la machinerie et d'autres industries de matériaux composites. Par le biais du transport international, les principales universités, les agences nationales de contrôle qualité, les laboratoires de recherche, les unités de production de matériaux réfractaires et les unités sidérurgiques reçoivent des expéditions vers des régions et des pays d'Asie, d'Europe et du Moyen-Orient. Méthodes de transport : Nous prenons en charge le transport maritime, le transport aérien, la livraison express et le transport ferroviaire.