- Overview

- Parameter

- Inquiry

- Related Products

Fire assay is the industry standard process for obtaining gold and platinum group element (PGE) concentrations from high-grade ores. Lead collection gold fire assay is considered the most definitive technique for gold analysis.

FIRE ASSAY ADVANTAGE

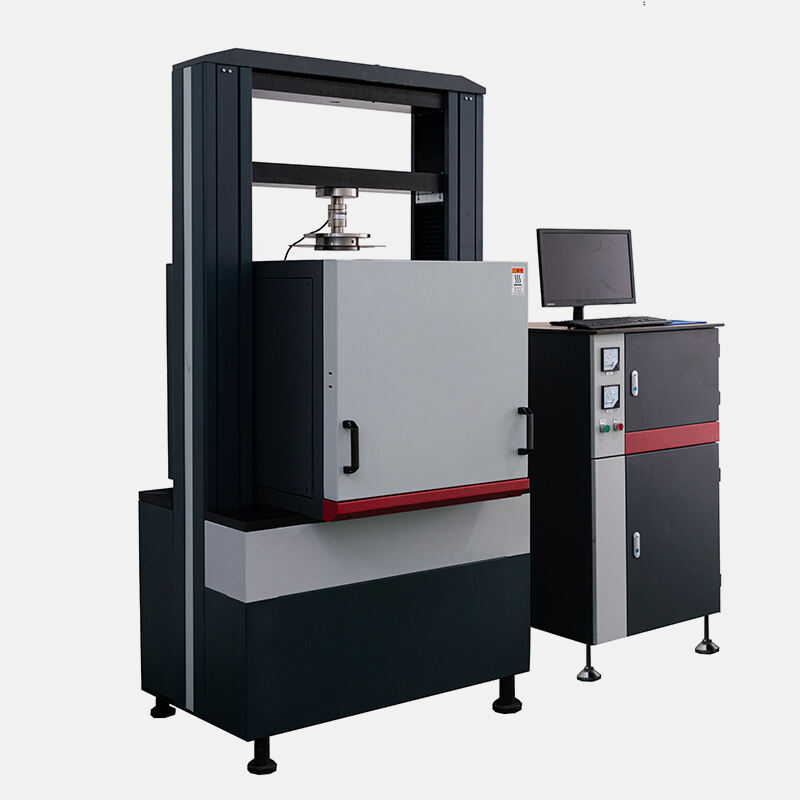

Electric Cupellation Furnace

Fire assay is the industry standard process for obtaining gold and platinum group element (PGE) concentrations from high-grade ores. Lead collection gold fire assay is considered the most definitive technique for gold analysis. Platinum and palladium can also be determined by this method, but the full PGE six-element suite is best determined by nickel sulfide collection fire assay.

Lead collection fire assay is used to determine gold in all sample types, including rocks, drill core, soil and chip samples. It is possible to use either of the 25, 30 and 50 g standard methods depending on anticipated gold contents and degree of homogeneity expected.

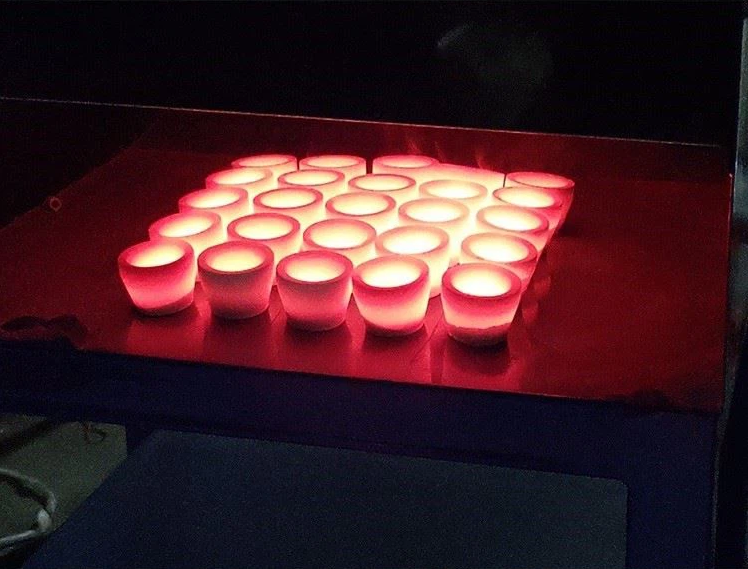

CUPELLATION

The pulverized sample is weighed and mixed with a fluxing agent. Lead is added as a collector. The sample is then heated in a furnace at about 1000 degrees. After about 20 minutes, the sample has fused and the precious metals and lead have separated from the silicate slag to form a 'button' in the bottom of the crucible. This button contains the precious metals.

Once the sample is removed from the furnace and cools, the lead button is separated from the silicate slag. The precious metals are then extracted by a process known as cupellation. During cupellation, the lead in the button oxidizes and is absorbed into the cupel leaving a precious metal bead known as a prill. The gold content of the prill is determined either by weighing (gravimetrically) or it is dissolved in aqua regia.

PRODUCT DESCRIPTION

●Silicon carbide elements mounted side the chamber provide even heating of cupels, have good resistance to thermal shock & offer extended working life at high temperatures.

● Fumes are extracted through an insulated exhaust duct, connecting with the exhausting system.

● Element over-temperature protection controller.

● Electronic, Digital, solid state temperature controller using Type-K thermocouple.

● ≥ 1150°C maximum operating temperature

● Three phase, 380 volts, 50-60 Hz

● Charge capacity of 100 or 50 for 6A,7A cupels

● Compatible with "multi-pour" loading / unloading system

● Easy to maintain and operate

● Door Opening:pneumatic or maual

TECHNICAL PARAMETER

| Model | Muffle Size(mm) | Dimension(mm) | Crucible Loading QTY | Max. Temperature(℃) | Power |

| YX-CF50 | 490x310x250 | 800x840x1600 | 50x6a,7a,7as | 1200 | 18kW,3ph |

| YX-CF100 | 610x540x350 | 980x1080x1700 | 100x6a,7a,7as | 1200 | 35kW,3ph |

Specifications

| High Temperature | 1200℃ |

| Furnace size(Depth-width-heigh) | 360x220x220mm |

| Temperature control accuracy | ±1℃ |

| Heating rate | 0-20℃/min |

| Rated power | 12kW |

| Rated voltage | 3x38V |

| Rated current | 3x20A |

| External dimension | 910x740x1660mm |

EN

EN

AR

AR

BG

BG

FR

FR

DE

DE

HI

HI

IT

IT

PL

PL

PT

PT

RU

RU

ES

ES

TL

TL

IW

IW

ID

ID

UK

UK

VI

VI

TH

TH

TR

TR

FA

FA

MS

MS

UR

UR

BN

BN

KM

KM

LO

LO

PA

PA

MY

MY

KK

KK