- Overview

- Parameter

- Inquiry

- Related Products

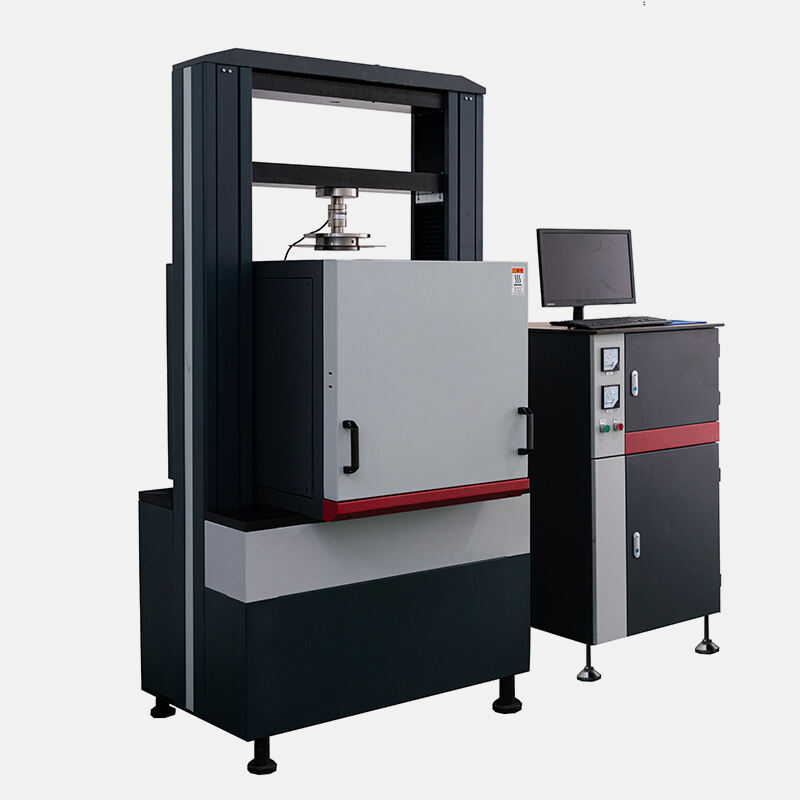

Product Description

This furnace is produced according to concerned Chinese standard,mostly designed to measure linear change on reheating performance of refractory products,also serve the purpose of box furnace proceed material 'sinter, smelting cum, heat treatment and etc. The brasque of the furnace adopts advanced fibre , heat retaining power best , energy conservation ; electric control system adopts intelligent controller, PID automatic calibration , six fixed heating schedule. The furnace processes heating-up,soaking automatically by using intelligent controller. In addition, possess of thermocouple breaking protection, current limiting function. Adopt specific double-deck furnace shell structure ,during test, the temperature rise of side-surface drops. The max. service temperature can be 1600 ℃ or 1700℃.Controller and furnace are for oneness.

Product Specification

| Specifications | |

| Model/specification | JZJ-LX17/20PA |

| Working temperature(℃) | 1680 |

| Max.temperature(℃) | 1700 |

| Hearth size(mm) | 200×250×400 |

| Heating-up rate(℃/min) | 0~15 |

| Temperature accuracy in soaking(℃) | ±1 |

| Range of air flow(L/min) | 1~10 |

| Heating element | MoSi2 |

| Brasque material | Fibre+Alumina bubble brick |

| Control Type | Intelligent |

| Experimental atmosphere | oxidizing atmosphere |

Specifications

| Model/specification | KYH-0 |

| Working temperature(℃) | 1600 |

| Max.temperature(℃) | 1650 |

| Hearth size(mm) | 320×240×190 |

| Heating-up rate(℃/min) | 0~8 |

| Temperature accuracy in soaking(℃) | ±2 |

| Range of air flow(L/min) | 1~10 |

| Size of mainframe(mm) | 800×700×1700 |

| Power supply | 380V 50Hz 13kW |

| Weight(kg) | 600 |

EN

EN

AR

AR

BG

BG

FR

FR

DE

DE

HI

HI

IT

IT

PL

PL

PT

PT

RU

RU

ES

ES

TL

TL

IW

IW

ID

ID

UK

UK

VI

VI

TH

TH

TR

TR

FA

FA

MS

MS

UR

UR

BN

BN

KM

KM

LO

LO

PA

PA

MY

MY

KK

KK