- Overview

- Parameter

- Inquiry

- Related Products

Description

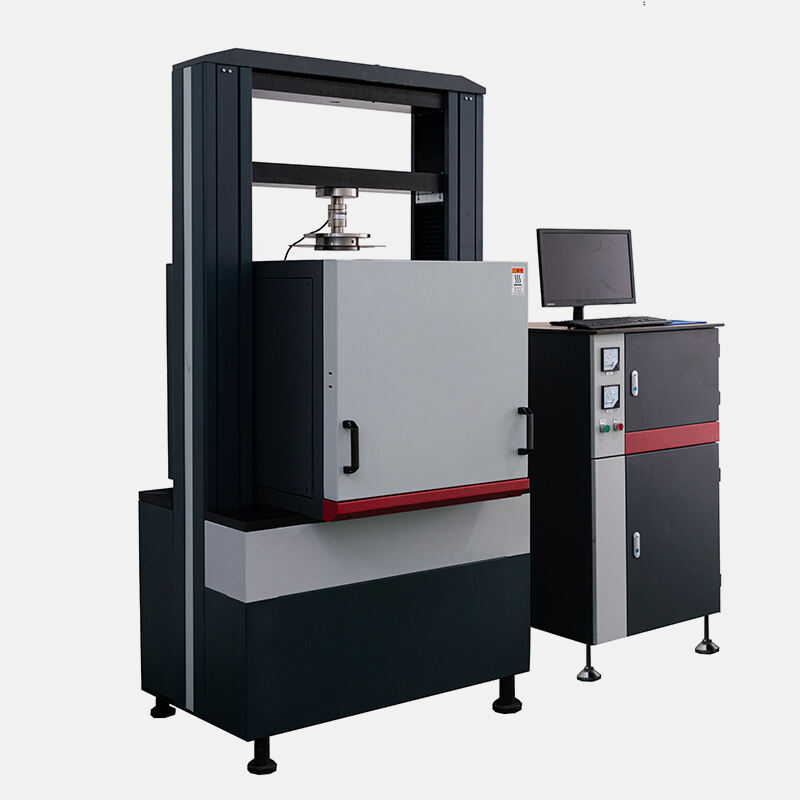

The high-temperature permeability tester is primarily used to test the permeability of investment casting molds. Considering the large size and weight of typical investment casting alloy samples, the instrument utilizes a robust structure to simultaneously heat and test four samples. Custom-designed gas pipes ensure that the large-mass samples do not bend under high temperatures, thus preventing any impact on the test results.

The high-temperature permeability tester features an intelligent temperature control module for precise temperature measurement and control, PLC control for movement, and software for data acquisition and processing. A digital gas flow meter provides real-time monitoring and automatic data recording. It boasts advantages such as fast data acquisition, strong anti-interference capabilities, and low failure rate.

The high-temperature permeability tester meets testing standards such as HB5352.4-2004 (Investment Casting Mold Shell Performance Test Methods, Part 4: Permeability Measurement) and JB/T4153 (High-Temperature Permeability Test Method for Investment Casting Shells).

The testing principle of the high-temperature permeability tester is as follows: The sample is heated to the test temperature and maintained at the specified temperature distribution. Simultaneously, gas is passed through the sample at a constant pressure, and the gas flow rate data is recorded in real time, generating a "flow rate-time-temperature" curve.

Specification

Specifications

| Air flow range(cm³/min) | <50 |

| Working temperature(℃) | room temperature(10~35) |

| Sample size(mm) | φ50×50 |

| Gas output pressure(MPa) | 0.1~0.4 |

| Inflation pressure(MPa) | 0.1-0.15 |

| Atmosphere of hearth | air,N₂ |

| Size of mainframe(mm) | 510×600×680 |

| Weight(kg) | 30 |

EN

EN

AR

AR

BG

BG

FR

FR

DE

DE

HI

HI

IT

IT

PL

PL

PT

PT

RU

RU

ES

ES

TL

TL

IW

IW

ID

ID

UK

UK

VI

VI

TH

TH

TR

TR

FA

FA

MS

MS

UR

UR

BN

BN

KM

KM

LO

LO

PA

PA

MY

MY

KK

KK