- Overview

- Inquiry

- Related Products

Description

High-temperature melting characteristics refer to the analysis and testing of the characteristics of materials such as ceramics, glazes, metals, solders, alloys, glass, and carbon under high-temperature conditions, including the transition from solid to liquid phase and the characteristics of the coexisting solid and liquid phases. It can analyze parameters such as softening point, melting point temperature, melting speed, fusion temperature, flow temperature, contact angle, expansion effect, surface tension, and theoretical viscosity of the tested material. By identifying various characteristic shapes and key temperatures, it helps optimize the material production process.

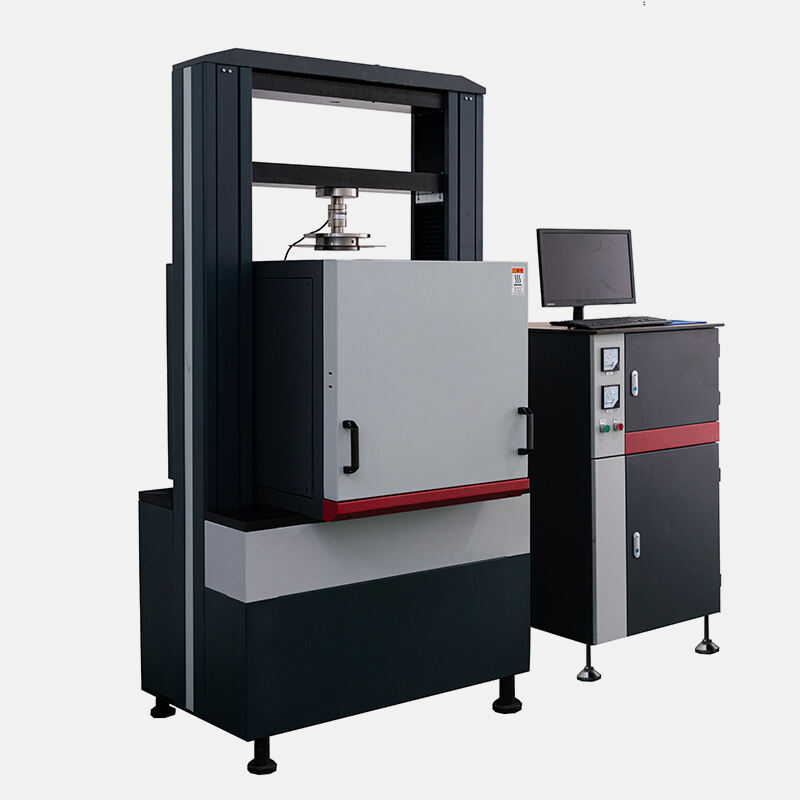

The high-temperature melting characteristics tester uses non-contact technology, performing image analysis by subjecting the sample to thermal treatment that replicates industrial processing environments. It automatically identifies characteristic temperatures and data in various regions, recording the entire process of the sample's state changes to meet the comprehensive analysis needs of product development and users.

The high-temperature melting characteristics tester uses a GM1800 high-temperature silicon molybdenum rod as the heating element, a B-type thermocouple for temperature measurement, a high-precision temperature control module for precise control of the heating rate, and an industrial image acquisition system to capture images and display them on a computer monitor. The digital imaging system and automatic recognition function completely overcome human interference. After the experiment, a test report can be printed, which includes image and temperature information. One experiment can simultaneously collect and analyze image information and data for three samples.

The high-temperature melting characteristics analyzer can achieve the following:

1. Measure and record the sintering shrinkage rate of materials under non-contact conditions, and analyze the dimensional changes of the sample, i.e., changes in height, width, and area.

2. Real-time measurement of the deformation of regular or irregularly shaped samples during the sintering process;

3. Determine various characteristic temperatures: sintering point, softening point, melting temperature, hemispherical temperature, flow temperature, etc.;

4. Assist in analyzing the wetting behavior between the melt and the substrate;

5. Determine the sintering process for ceramics or glazes;

6. Analyze the high-temperature deformation of core materials;

EN

EN

AR

AR

BG

BG

FR

FR

DE

DE

HI

HI

IT

IT

PL

PL

PT

PT

RU

RU

ES

ES

TL

TL

IW

IW

ID

ID

UK

UK

VI

VI

TH

TH

TR

TR

FA

FA

MS

MS

UR

UR

BN

BN

KM

KM

LO

LO

PA

PA

MY

MY

KK

KK