Detailed explanation of the working principle and use of muffle furnace

1.Working principle of muffle furnace

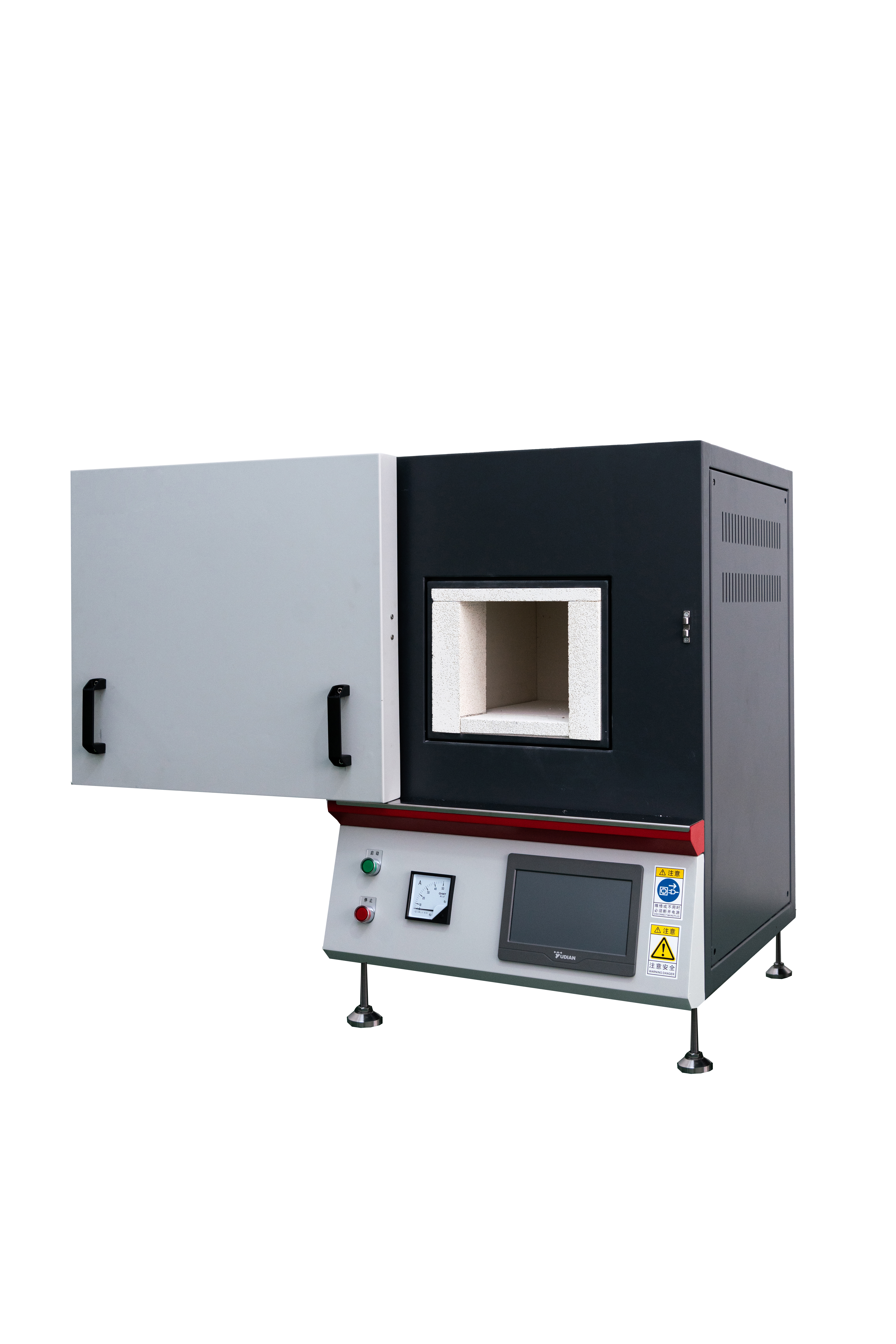

Muffle furnace increases the temperature inside the heater by resistance heating, and transfers the temperature of the heating area to the heated material by heat conduction, so that the material is evenly heated. Its main components include heater, temperature control system and ventilation system. Among them, the heater is heated by resistance heating, the temperature control system controls the temperature to reach the required heating temperature through the temperature sensor, and the ventilation system is used to adjust the atmosphere composition and air pressure in the working environment.

2. Application field of muffle furnace

1). Heat treatment of metal materials

High Temperature Muffle furnace is widely used in the treatment of metal materials, such as preheating, quenching, tempering and annealing of casting molds, automotive parts, tool forgings, etc., so that the material has stronger hardness, toughness and wear resistance.

2). Molding, smelting

High temperature melting furnace is also suitable for heating treatment in various molding and smelting processes, such as glass molding, plastic products, ceramic sintering, etc.

3). Laboratory application

Since the muffle furnace can control the temperature of the heating area, it is widely used in various laboratories and other fields, such as material synthesis, inorganic chemical experiments, high-temperature physical experiments, etc.

In short, as a common heat treatment equipment, the muffle furnace is widely used in the heat treatment, forming, smelting and various laboratories of metal materials. Through resistance heating, the temperature inside the heater can be increased, and the temperature of the heating area can be transferred to the heated material through heat conduction, so that the material is evenly heated.

Recommended Products

Hot News

-

Working together with Chinese manufacturers, Indonesia's nickel and iron ore industry has taken a solid step forward in its upgrading process – JZJ automation equipment helps improve testing efficiency and accuracy.

2026-01-19

-

A must-read for beginners! A guide to avoiding pitfalls when buying a high-temperature flexural testing machine.

2026-01-12

-

From Nanyang to East Africa: China's "Fire Assay" Technology Illuminates the Future of Kenya's Mining Industry—The Launch of the Kyrgyz-Chinese Testing Equipment Container Laboratory

2025-12-30

-

Features of the Gold Test Ash Blowing Furnace

2025-12-22

-

Precisely measuring material "endurance" at high temperatures—Nanyang JZJ Testing Equipment Co., Ltd.'s high-temperature load-bearing creep tester is exported to the United States.

2025-12-17

-

The trusted choice of African mining giants! Nanyang JZJ Testing injects refined "core power" into Zimbabwe's gold mining industry.

2025-12-08

-

Working principle and application range of ambient temperature abrasion tester

2025-11-07

-

The main reagents used in fire assay and their functions

2025-10-13

-

Let you know about fire assay ash blowing furnace

2025-09-23

-

Refractoriness under load (RUL) and creep in compression (CIC) testing machine common troubleshooting

2025-08-25

EN

EN

AR

AR

BG

BG

FR

FR

DE

DE

HI

HI

IT

IT

PL

PL

PT

PT

RU

RU

ES

ES

TL

TL

IW

IW

ID

ID

UK

UK

VI

VI

TH

TH

TR

TR

FA

FA

MS

MS

UR

UR

BN

BN

KM

KM

LO

LO

PA

PA

MY

MY

KK

KK