Working together with Chinese manufacturers, Indonesia's nickel and iron ore industry has taken a solid step forward in its upgrading process – JZJ automation equipment helps improve testing efficiency and accuracy.

Recently, a large nickel-iron mine factory in Indonesia successfully imported several sets of advanced automated sample preparation equipment from China to continuously improve its analytical and testing capabilities for raw materials and finished products, optimize production processes, and ensure the stability and reliability of product quality. The factory purchased 12 T6 series fully automatic fusion machines and 12 fully automatic weighing instruments from Nanyang JZJ Testing Equipment Co., Ltd., a well-known laboratory equipment supplier in China. This move marks a new stage in the factory's intelligent laboratory and standardized process construction, and adds a significant achievement to Sino-Indonesian cooperation in the field of mining technology and equipment.

Meeting Challenges with Efficient and Precise Solutions

The exploration, mining, smelting, and trading of nickel-iron ore all require precise analysis of the chemical composition of the ore, intermediate products, and final products. Traditional sample preparation and weighing processes rely heavily on manual operation, which not only limits efficiency but also easily introduces errors due to human factors, making it difficult to fully meet the high standards of modern industrial production for data timeliness, accuracy, and consistency.

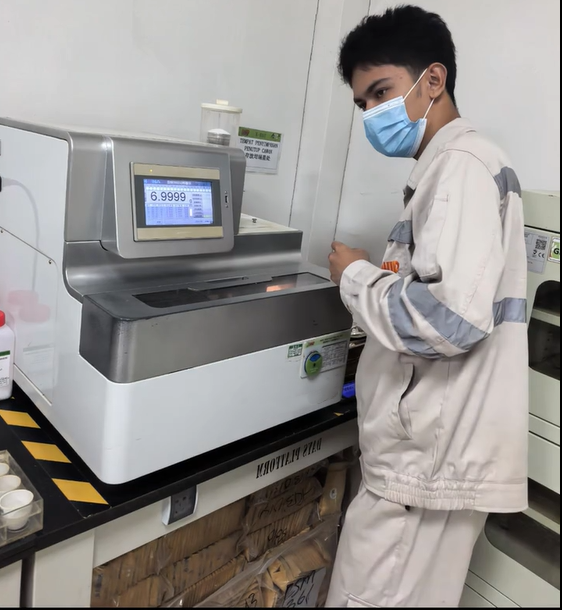

Facing the dual demands of increased production capacity and quality control, the Indonesian factory, after in-depth market research and technical comparisons, finally turned its attention to Nanyang JZJ, a Chinese brand with mature technology and a good reputation in the field of sample preparation. Its core products, the T6 fully automatic fusion machine and the fully automatic weighing instrument, have won the trust of customers with their high degree of automation, excellent stability, and precision.

Superior Equipment Lays a Solid Foundation for Accurate Analysis

The T6 fully automatic fusion machine purchased this time is one of Nanyang JZJ's flagship products. It is specifically designed for glass bead sample preparation for analytical methods such as XRF and ICP, and can automatically complete a series of complex steps including weighing, adding flux, mixing, melting, pouring, cooling, and demolding. Its features include:

• High efficiency and stability: The multi-station design supports continuous batch processing, significantly improving sample preparation efficiency; the precise temperature control system and mature melting program ensure that each fusion reaches the optimal state, producing uniform, flat, and high-quality glass beads. • Safe and Intelligent: Fully enclosed operation effectively avoids potential risks to operators from high temperatures and chemical reagents; the intuitive human-machine interface facilitates program editing and monitoring, reducing over-reliance on operator experience.

• Reliable and Durable: Designed specifically for industrial environments, it can adapt to high-intensity continuous operation, ensuring seamless integration of production and testing processes.

The accompanying fully automatic weighing instrument revolutionizes the sample and reagent weighing process. It can:

• Precise Weighing: Uses high-precision sensors to ensure milligram-level weighing accuracy, guaranteeing the reliability of analytical data from the source.

• Unattended Operation: Automatically completes sample container identification, taring, sample addition, weighing, recording, and data transmission, freeing up manpower and eliminating human recording errors.

• Seamless Integration: Can be linked with the fusion machine or Laboratory Information Management System (LIMS) to achieve full-process automation and data traceability from weighing to sample preparation.

Collaborative Win-Win, Contributing to the High-Quality Development of the Indonesian Mining Industry

The deployment of these 6 T6 fusion machines and 4 fully automatic weighing instruments will bring significant benefits to the Indonesian nickel-iron mine plant:

1. Improved Detection Efficiency and Capacity: The 24/7 continuous operation capability of the automated equipment will greatly shorten the sample preparation cycle, accelerate laboratory analysis speed, and provide faster data support for production decisions.

2. Guaranteed Data Accuracy and Consistency: Full-process automation minimizes errors caused by human intervention, making the results of samples prepared by different batches and different operators highly comparable, improving the level of quality control.

3. Reduced Labor Costs and Work Intensity: Frees laboratory personnel from repetitive and high-risk manual labor, allowing them to focus on higher-value analytical method development and data interpretation.

4. Promotes Laboratory Standardization and Intelligence: Drives the laboratory towards modern, digital management, building a solid technical foundation for the long-term sustainable development of the plant. The Overseas Sales Director of Nanyang JZJ Testing Equipment Co., Ltd. stated: "We are very honored that our products can serve this important nickel-iron mining project in Indonesia. This cooperation is not only a recognition of JZJ's product technology strength, but also a vivid embodiment of how Chinese intelligent equipment is contributing to the transformation and upgrading of the global mining industry. We will provide comprehensive installation, training, and after-sales services to ensure the stable operation of the equipment and grow together with our customers."

The success of this cooperation is not only another important achievement for Nanyang JZJ Testing Equipment Co., Ltd. in the international market, showcasing the competitiveness of "Made in China" in the field of high-end laboratory instruments, but also provides a good example for the Indonesian resource processing industry to achieve cost reduction, efficiency improvement, and industrial upgrading through the introduction of advanced technological equipment. Looking ahead, with the in-depth advancement of the Belt and Road Initiative, cooperation between China and Indonesia in the field of industrial technology and equipment will undoubtedly become closer, jointly writing a new chapter of mutual benefit and win-win results.

Recommended Products

Hot News

-

Working together with Chinese manufacturers, Indonesia's nickel and iron ore industry has taken a solid step forward in its upgrading process – JZJ automation equipment helps improve testing efficiency and accuracy.

2026-01-19

-

A must-read for beginners! A guide to avoiding pitfalls when buying a high-temperature flexural testing machine.

2026-01-12

-

From Nanyang to East Africa: China's "Fire Assay" Technology Illuminates the Future of Kenya's Mining Industry—The Launch of the Kyrgyz-Chinese Testing Equipment Container Laboratory

2025-12-30

-

Features of the Gold Test Ash Blowing Furnace

2025-12-22

-

Precisely measuring material "endurance" at high temperatures—Nanyang JZJ Testing Equipment Co., Ltd.'s high-temperature load-bearing creep tester is exported to the United States.

2025-12-17

-

The trusted choice of African mining giants! Nanyang JZJ Testing injects refined "core power" into Zimbabwe's gold mining industry.

2025-12-08

-

Working principle and application range of ambient temperature abrasion tester

2025-11-07

-

The main reagents used in fire assay and their functions

2025-10-13

-

Let you know about fire assay ash blowing furnace

2025-09-23

-

Refractoriness under load (RUL) and creep in compression (CIC) testing machine common troubleshooting

2025-08-25

EN

EN

AR

AR

BG

BG

FR

FR

DE

DE

HI

HI

IT

IT

PL

PL

PT

PT

RU

RU

ES

ES

TL

TL

IW

IW

ID

ID

UK

UK

VI

VI

TH

TH

TR

TR

FA

FA

MS

MS

UR

UR

BN

BN

KM

KM

LO

LO

PA

PA

MY

MY

KK

KK