High-Temperature Flexural Testing Machine Operation Guide: Even beginners can easily get started.

In materials science laboratories, high-temperature flexural testing machines are essential tools for studying the high-temperature mechanical properties of materials. For beginners, facing complex equipment and operating procedures can be daunting. Don't worry, this comprehensive guide to operating a high-temperature flexural testing machine will guide you step-by-step, allowing you to easily familiarize yourself with the equipment and quickly master the operating essentials.

Comprehensive Guide to Operating a High-Temperature Flexural Testing Machine

I. Equipment Overview and Safety Precautions

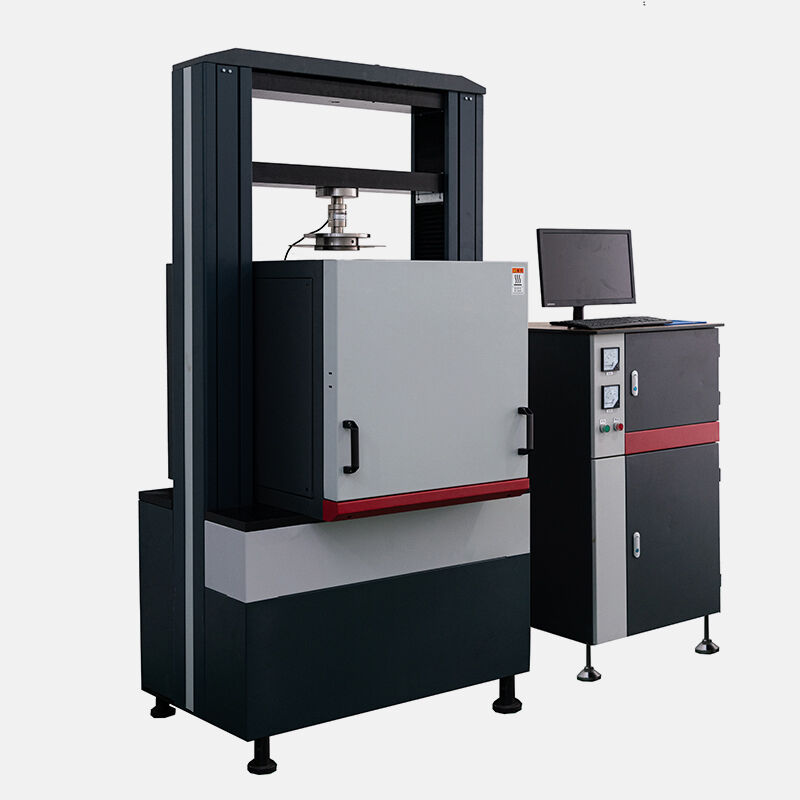

Before officially operating the high-temperature flexural testing machine, it is essential to have a comprehensive understanding of the equipment. The high-temperature flexural testing machine mainly consists of a main frame, heating system, force measurement system, fixture device, and control system. The main frame is the main structure of the equipment, supporting the mechanical parts of the entire testing process; the heating system provides a high-temperature environment, simulating the high-temperature working conditions of the material in actual applications; the force measurement system is responsible for measuring the flexural strength and other mechanical properties of the material at high temperatures; the fixture device is used to fix the sample, ensuring the stability of the sample's position during the test; and the control system is the brain of the entire equipment, used to set test parameters, control the testing process, and collect data.

Safety is the primary prerequisite for operating a high-temperature flexural testing machine. Because the equipment involves high temperatures and mechanical loading, safety procedures must be strictly followed during operation. Before operation, be sure to wear protective equipment, such as heat-resistant gloves and safety glasses, to prevent burns and accidental injuries. Check the surrounding area for flammable and explosive materials to ensure a safe testing environment. Also, familiarize yourself with the location of the emergency stop button so that you can quickly shut down the machine in case of an emergency, preventing equipment damage and personal injury.

II. Pre-Test Preparations

Pre-test preparations are crucial for ensuring the smooth progress of the test. First, check that all components of the testing machine are functioning correctly. Turn on the equipment and check that the heating system is heating up properly, the force measurement system is zeroed, and the fixture device is securely installed. If any abnormalities are found, immediately contact equipment maintenance personnel for inspection and repair; do not attempt to operate the equipment forcibly.

Next, prepare the sample according to the test requirements. The size and shape of the sample should conform to relevant standards or experimental requirements, and usually require accurate measurement and processing. When installing the specimen, ensure it is placed in the correct position in the fixture. The clamping force of the fixture should be moderate, ensuring the specimen does not loosen during the test, but also preventing damage due to excessive clamping force. Simultaneously, set appropriate test parameters based on the test material and purpose, including heating temperature, heating rate, and loading speed. These parameters should be set according to relevant standards or experimental procedures to ensure the accuracy and repeatability of the test results.

III. Test Operation Procedure

Once everything is ready, the test operation can begin. First, start the equipment and begin heating according to the set parameters. During heating, closely observe the temperature changes of the heating system to ensure the temperature rises steadily at the predetermined rate and reaches the set test temperature. Once the temperature stabilizes, begin the loading operation. Slowly apply the load through the control system, observing the deformation of the specimen and the readings of the force measurement system. Throughout the entire test process, maintain concentration and be prepared to deal with any potential abnormalities, such as specimen fracture or equipment malfunction.

When the specimen reaches its strength limit and fractures, the test ends. At this point, record the key data from the test process, such as the load at fracture and the amount of deformation. This data will be used for subsequent analysis and calculations to determine performance indicators such as the material's high-temperature flexural strength. After the test, do not immediately turn off the equipment; wait for the heating system to cool naturally to a safe temperature to avoid injury to equipment and personnel due to high temperatures.

IV. Data Processing and Equipment Maintenance

After the test is completed, data processing is a crucial step in verifying the test results. Import the collected data into professional data analysis software for organization and analysis. Based on the test purpose, calculate performance parameters such as the material's high-temperature flexural strength and elastic modulus, and compare them with theoretical or standard values to evaluate the accuracy of the test results. If data anomalies are found, analyze the reasons and, if necessary, repeat the test.

At the same time, equipment maintenance and upkeep should not be neglected. After each test, clean and inspect the equipment. Clean any residue in the heating furnace to prevent it from affecting the heating effect of the next test. Check the mechanical components of the equipment for wear or looseness, and perform maintenance and tightening as needed. Regularly calibrate and maintain the equipment to ensure its long-term stable operation. Good equipment maintenance not only extends the service life of the equipment but also guarantees the reliability of the test results.

Recommended Products

Hot News

-

High-Temperature Flexural Testing Machine Operation Guide: Even beginners can easily get started.

2026-02-03

-

Working together with Chinese manufacturers, Indonesia's nickel and iron ore industry has taken a solid step forward in its upgrading process – JZJ automation equipment helps improve testing efficiency and accuracy.

2026-01-19

-

A must-read for beginners! A guide to avoiding pitfalls when buying a high-temperature flexural testing machine.

2026-01-12

-

From Nanyang to East Africa: China's "Fire Assay" Technology Illuminates the Future of Kenya's Mining Industry—The Launch of the Kyrgyz-Chinese Testing Equipment Container Laboratory

2025-12-30

-

Features of the Gold Test Ash Blowing Furnace

2025-12-22

-

Precisely measuring material "endurance" at high temperatures—Nanyang JZJ Testing Equipment Co., Ltd.'s high-temperature load-bearing creep tester is exported to the United States.

2025-12-17

-

The trusted choice of African mining giants! Nanyang JZJ Testing injects refined "core power" into Zimbabwe's gold mining industry.

2025-12-08

-

Working principle and application range of ambient temperature abrasion tester

2025-11-07

-

The main reagents used in fire assay and their functions

2025-10-13

-

Let you know about fire assay ash blowing furnace

2025-09-23

EN

EN

AR

AR

BG

BG

FR

FR

DE

DE

HI

HI

IT

IT

PL

PL

PT

PT

RU

RU

ES

ES

TL

TL

IW

IW

ID

ID

UK

UK

VI

VI

TH

TH

TR

TR

FA

FA

MS

MS

UR

UR

BN

BN

KM

KM

LO

LO

PA

PA

MY

MY

KK

KK