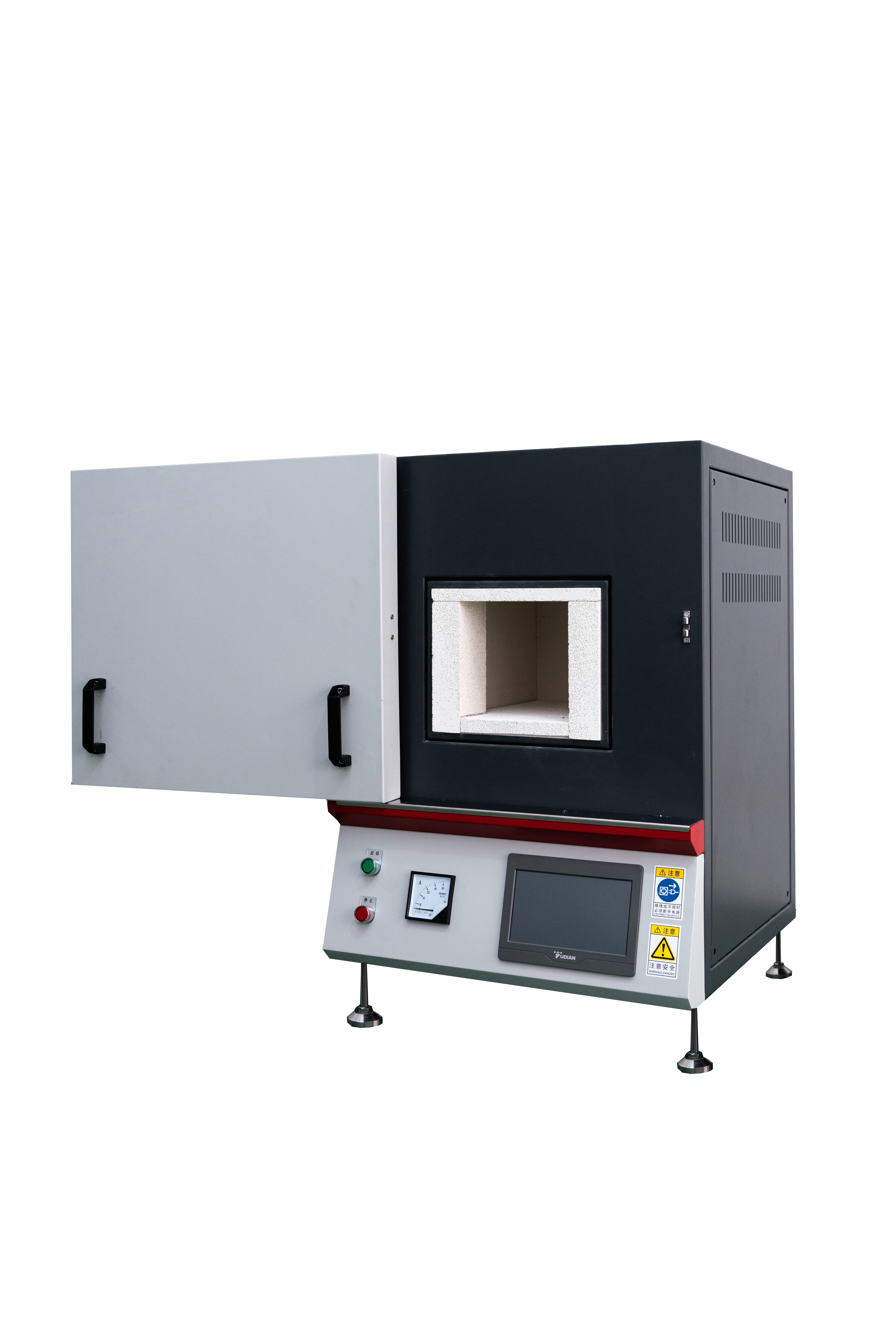

What are the characteristics of ceramic fiber fast heating muffle furnace?

The characteristics of the ceramic fiber fast heating muffle furnace are mainly reflected in the following aspects:

Fast heating speed:

Ceramic fiber materials have low thermal conductivity and low heat capacity, which enables the furnace to respond quickly to heating instructions and achieve rapid heating. This greatly shortens the heating time in experiments or production processes and improves work efficiency.

High efficiency and energy saving:

Due to the excellent thermal insulation performance of ceramic fiber, the heat in the furnace is not easy to dissipate, thereby reducing energy waste. This enables the ceramic fiber fast heating muffle furnace to maintain low energy consumption during long-term operation.

Good temperature uniformity:

The ceramic fiber material has a low thermal conductivity, which helps to reduce the temperature gradient in the furnace and make the temperature in the furnace more uniform. This is crucial for experiments or production processes that require precise temperature control.

Light weight and small size:

Compared with traditional muffle furnaces, the ceramic fiber fast heating muffle furnace uses lightweight materials, which greatly reduces the overall weight and is more compact. This makes the equipment easier to move and install, saving space in laboratories or production workshops.

Long service life:

Ceramic fiber materials have high thermal shock resistance and corrosion resistance, and can operate stably for a long time in harsh high temperature environments. This extends the service life of the equipment and reduces the frequency and cost of replacing the equipment.

Easy to maintain:

The structure of the ceramic fiber heating fast muffle furnace is relatively simple and easy to disassemble and clean. This makes the maintenance of the equipment more convenient and quick, and reduces the maintenance cost.

Safe and reliable:

The equipment is usually equipped with an overheating protection device and a temperature control system, which can automatically cut off the power in the event of overheating or abnormal conditions to ensure safety during use.

Wide application:

The ceramic fiber heating fast muffle furnace is suitable for various experiments and production processes that require high temperature heating, such as material synthesis, heat treatment, sintering, melting, etc. Its wide range of application areas makes the equipment have high practical value.

In summary, the ceramic fiber heating fast muffle furnace has been widely used in laboratories and industrial production due to its fast heating speed, high efficiency and energy saving, good temperature uniformity, light weight, small size, long service life, easy maintenance, and safety and reliability.

Recommended Products

Hot News

-

Working together with Chinese manufacturers, Indonesia's nickel and iron ore industry has taken a solid step forward in its upgrading process – JZJ automation equipment helps improve testing efficiency and accuracy.

2026-01-19

-

A must-read for beginners! A guide to avoiding pitfalls when buying a high-temperature flexural testing machine.

2026-01-12

-

From Nanyang to East Africa: China's "Fire Assay" Technology Illuminates the Future of Kenya's Mining Industry—The Launch of the Kyrgyz-Chinese Testing Equipment Container Laboratory

2025-12-30

-

Features of the Gold Test Ash Blowing Furnace

2025-12-22

-

Precisely measuring material "endurance" at high temperatures—Nanyang JZJ Testing Equipment Co., Ltd.'s high-temperature load-bearing creep tester is exported to the United States.

2025-12-17

-

The trusted choice of African mining giants! Nanyang JZJ Testing injects refined "core power" into Zimbabwe's gold mining industry.

2025-12-08

-

Working principle and application range of ambient temperature abrasion tester

2025-11-07

-

The main reagents used in fire assay and their functions

2025-10-13

-

Let you know about fire assay ash blowing furnace

2025-09-23

-

Refractoriness under load (RUL) and creep in compression (CIC) testing machine common troubleshooting

2025-08-25

EN

EN

AR

AR

BG

BG

FR

FR

DE

DE

HI

HI

IT

IT

PL

PL

PT

PT

RU

RU

ES

ES

TL

TL

IW

IW

ID

ID

UK

UK

VI

VI

TH

TH

TR

TR

FA

FA

MS

MS

UR

UR

BN

BN

KM

KM

LO

LO

PA

PA

MY

MY

KK

KK