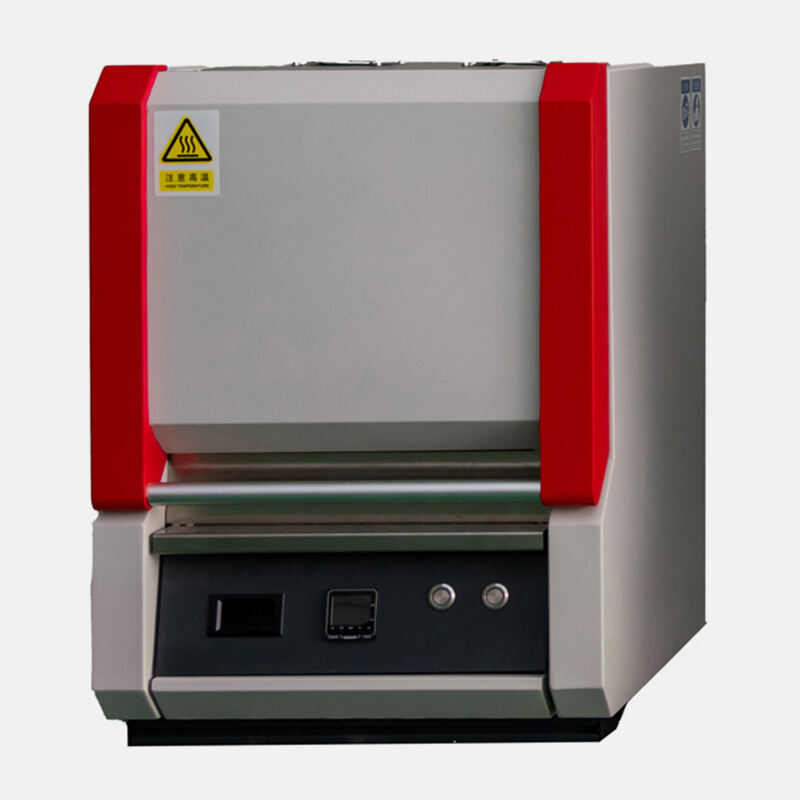

What materials are suitable for high temperature muffle furnace testing?

High-temperature muffle furnaces have a wide range of applications in materials testing, primarily for the following types of materials:

Metallic Materials:

High-temperature muffle furnaces are used for melting, refining, and alloying metals. By controlling the temperature and atmosphere within the furnace, metal materials with specific properties can be prepared.

High-temperature muffle furnaces also play an important role in testing the performance of metal materials, such as determining tensile strength and elongation.

In addition, high-temperature muffle furnaces are used for heat treatment processes such as annealing, solution treatment, and aging to improve mechanical properties and corrosion resistance.

Ceramic Materials:

Ceramic materials require high-temperature treatment during the firing process to achieve densification and improve performance. High-temperature muffle furnaces provide a stable heating environment, ensuring a uniform temperature distribution during firing, resulting in optimal firing results.

High-temperature muffle furnaces are also used for testing the performance of ceramic materials, such as determining hardness and wear resistance.

Organic Matter:

High-temperature muffle furnaces can rapidly decompose organic matter at high temperatures, enabling component analysis. In fields such as chemical analysis and environmental monitoring, high-temperature muffle furnaces are often used to process samples to extract elements or compounds, facilitating subsequent analytical testing.

Other Inorganic Non-metallic Materials:

High-temperature muffle furnaces can also be used for the preparation and performance testing of materials such as glass and enamel. In the glass industry, high-temperature muffle furnaces are used for firing and melting glass products; in the enamel industry, they are used for processes such as sintering and annealing enamel products.

New Energy Materials:

With the continuous development of the new energy industry, the application of high-temperature muffle furnaces in the new energy materials field is becoming increasingly widespread. For example, in the photovoltaic industry, high-temperature muffle furnaces are used in processes such as the preparation of polycrystalline silicon and the solidification of single crystal silicon; in the fuel cell field, high-temperature muffle furnaces are used for electrode preparation, among other applications.

Coal Quality Analysis:

High-temperature muffle furnaces can also be used for coal quality analysis, such as determining parameters such as moisture, ash, and volatile matter, as well as performing ash melting point and ash composition analysis. These analytical data are of great significance for coal mining, utilization, and environmental protection.

In summary, high-temperature muffle furnaces, with their efficient and precise heating capabilities, play an important role in materials testing. By precisely controlling heating conditions and atmosphere, high-temperature muffle furnaces can heat a variety of materials, perform performance testing, and perform composition analysis, providing strong support for materials science research, industrial production, and the development of new materials.

Recommended Products

Hot News

-

High-performance, cost-effective high-temperature flexural strength testing machine purchasing guide

2026-02-12

-

High-Temperature Flexural Testing Machine Operation Guide: Even beginners can easily get started.

2026-02-03

-

Working together with Chinese manufacturers, Indonesia's nickel and iron ore industry has taken a solid step forward in its upgrading process – JZJ automation equipment helps improve testing efficiency and accuracy.

2026-01-19

-

A must-read for beginners! A guide to avoiding pitfalls when buying a high-temperature flexural testing machine.

2026-01-12

-

From Nanyang to East Africa: China's "Fire Assay" Technology Illuminates the Future of Kenya's Mining Industry—The Launch of the Kyrgyz-Chinese Testing Equipment Container Laboratory

2025-12-30

-

Features of the Gold Test Ash Blowing Furnace

2025-12-22

-

Precisely measuring material "endurance" at high temperatures—Nanyang JZJ Testing Equipment Co., Ltd.'s high-temperature load-bearing creep tester is exported to the United States.

2025-12-17

-

The trusted choice of African mining giants! Nanyang JZJ Testing injects refined "core power" into Zimbabwe's gold mining industry.

2025-12-08

-

Working principle and application range of ambient temperature abrasion tester

2025-11-07

-

The main reagents used in fire assay and their functions

2025-10-13

EN

EN

AR

AR

BG

BG

FR

FR

DE

DE

HI

HI

IT

IT

PL

PL

PT

PT

RU

RU

ES

ES

TL

TL

IW

IW

ID

ID

UK

UK

VI

VI

TH

TH

TR

TR

FA

FA

MS

MS

UR

UR

BN

BN

KM

KM

LO

LO

PA

PA

MY

MY

KK

KK