What is a high temperature dilatometer?

A high temperature dilatometer is a special instrument used to measure the expansion or contraction properties of solid materials under high temperature conditions. It is mainly used to study parameters such as the thermal expansion coefficient, thermal stress and thermal stability of materials. In laboratories and industrial fields, high temperature dilatometers are widely used in materials science, engineering materials research, and the evaluation and testing of material properties under high temperature environments.

1. Structure and working principle

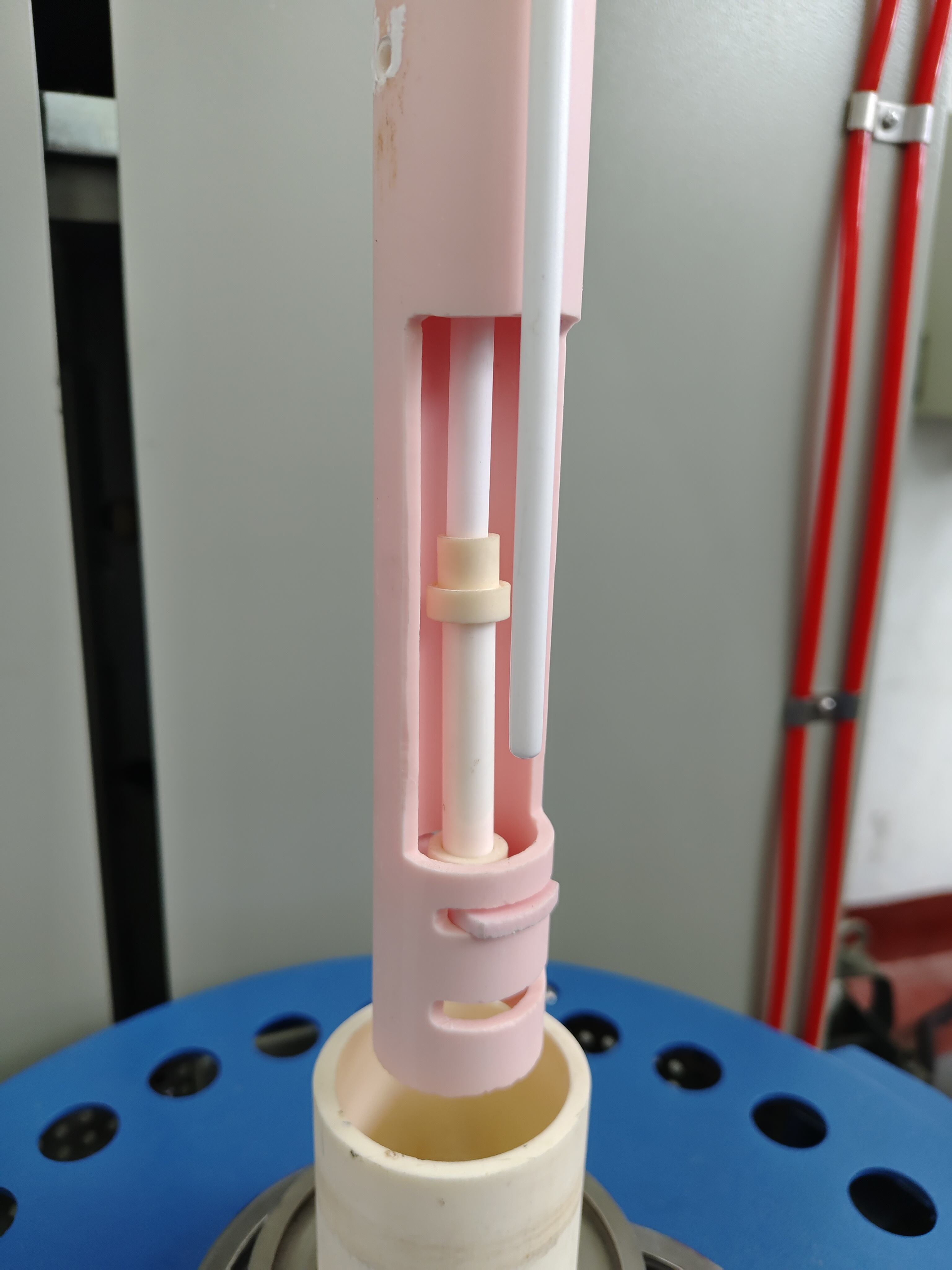

A high temperature dilatometer usually consists of a sample stage, a measuring sensor, a heating device and a control system. Its working principle is based on analyzing the thermal expansion properties of materials by heating the sample and measuring its volume change. Specifically, the sample is placed on the sample stage, and then the heating device controls the heating source (resistance heating, electron beam heating, etc.) to heat the sample to a set high temperature environment. During the heating process, the measuring sensor monitors and records the volume change of the sample in real time, thereby calculating the thermal expansion coefficient or expansion curve of the material

2. Application fields

1. Material research and development: High temperature dilatometers are used to evaluate the thermal expansion characteristics of different materials under high temperature conditions, helping researchers understand the thermal stability and thermomechanical properties of materials, thereby optimizing material formulations and process parameters.

2. Industrial production and quality control: In the metal, ceramic, glass and other industrial fields, high temperature dilatometers are used for quality control and product certification to ensure the stability and reliability of products under high temperature conditions.

3. Thermal expansion and contraction test: used to evaluate the dimensional changes of materials under temperature changes, especially in the manufacture of precision parts and equipment.

4. Material performance evaluation: high temperature expansion tests are performed on new materials, composite materials and coating materials to evaluate their adaptability and performance in extreme environments.

3. Key technical indicators

The key technical indicators of high temperature dilatometers include measurement range, temperature control accuracy, measurement accuracy, sample stage design and data analysis software. Different instruments have different temperature ranges and accuracy requirements, and it is particularly important to choose an instrument that suits specific application requirements.

In short, the high temperature dilatometer is an important instrument dedicated to measuring the thermal expansion properties of solid materials under high temperature conditions. By accurately measuring the thermal expansion coefficient and expansion behavior of materials, the high temperature dilatometer plays a key role in materials research, industrial production and quality control, and provides important experimental data and basis for materials science and engineering technology.

Recommended Products

Hot News

-

Working together with Chinese manufacturers, Indonesia's nickel and iron ore industry has taken a solid step forward in its upgrading process – JZJ automation equipment helps improve testing efficiency and accuracy.

2026-01-19

-

A must-read for beginners! A guide to avoiding pitfalls when buying a high-temperature flexural testing machine.

2026-01-12

-

From Nanyang to East Africa: China's "Fire Assay" Technology Illuminates the Future of Kenya's Mining Industry—The Launch of the Kyrgyz-Chinese Testing Equipment Container Laboratory

2025-12-30

-

Features of the Gold Test Ash Blowing Furnace

2025-12-22

-

Precisely measuring material "endurance" at high temperatures—Nanyang JZJ Testing Equipment Co., Ltd.'s high-temperature load-bearing creep tester is exported to the United States.

2025-12-17

-

The trusted choice of African mining giants! Nanyang JZJ Testing injects refined "core power" into Zimbabwe's gold mining industry.

2025-12-08

-

Working principle and application range of ambient temperature abrasion tester

2025-11-07

-

The main reagents used in fire assay and their functions

2025-10-13

-

Let you know about fire assay ash blowing furnace

2025-09-23

-

Refractoriness under load (RUL) and creep in compression (CIC) testing machine common troubleshooting

2025-08-25

EN

EN

AR

AR

BG

BG

FR

FR

DE

DE

HI

HI

IT

IT

PL

PL

PT

PT

RU

RU

ES

ES

TL

TL

IW

IW

ID

ID

UK

UK

VI

VI

TH

TH

TR

TR

FA

FA

MS

MS

UR

UR

BN

BN

KM

KM

LO

LO

PA

PA

MY

MY

KK

KK